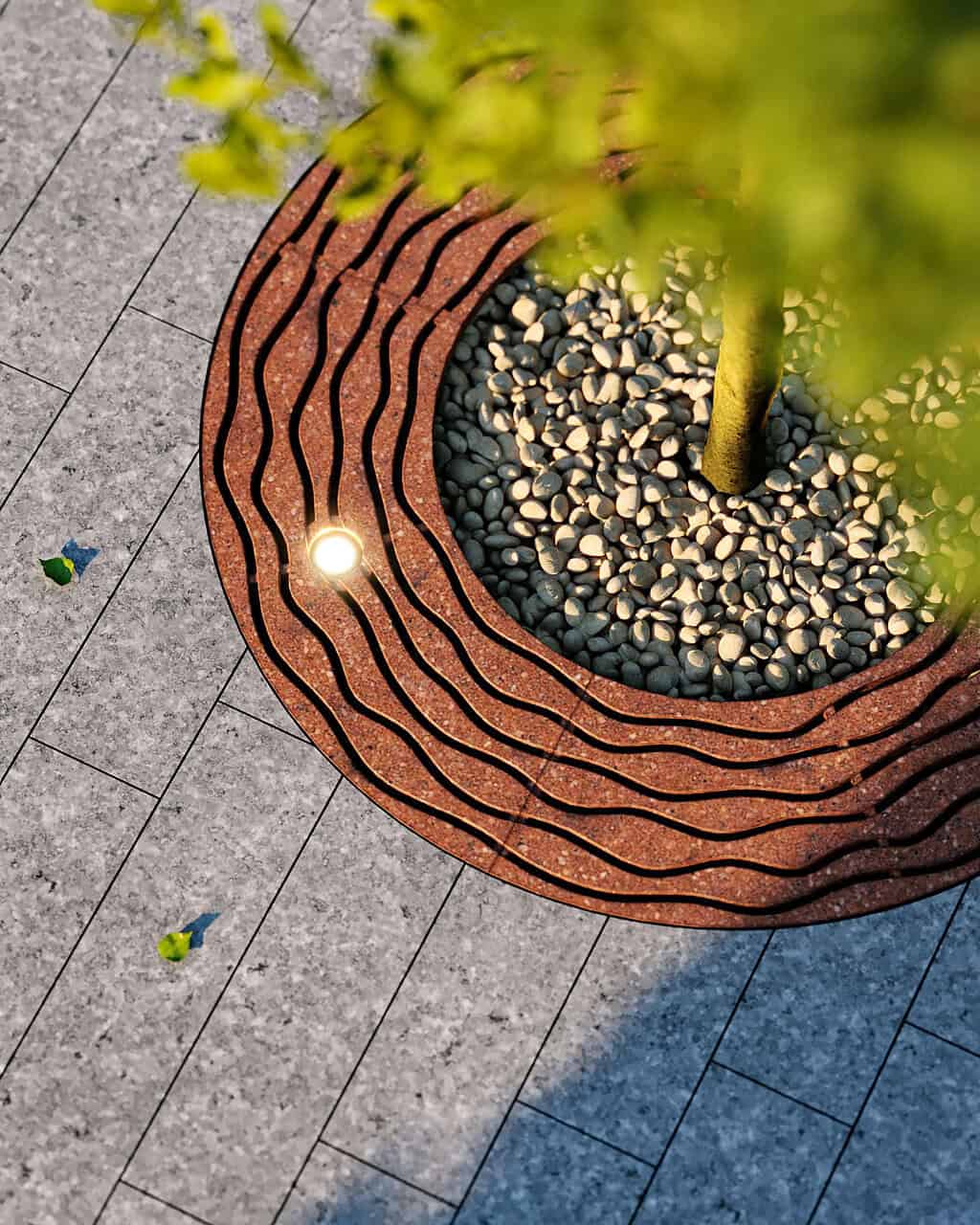

Jonite Stone Hardscape Products

Jonite is your hardscape partner that recognises the transformational potential of a space. Our eye for detail, engaging designs and dedication to lasting value enables architects to realise their vision

Why Jonite

Stone Aesthetics

Corrosion Proof

Slip Resistance

Rust Resistant

High Strength

Sustainable

Fire Rated

Stone Aesthetics

Frequently

Asked Questions

What is the life cycle of Jonite products?

The general life cycle of Jonite products is minimally 30 years or more

Minimum Impact Disposal – Can Jonite be recycled? Can it be broken down?

Jonite can be crushed and broken down into smaller aggregates as road base.

Are Jonite products sustainable?

Jonite commits to environmentally sustainable practices. We actively manage our energy, water, and waste with the future in mind. They use at least 30% recycled aggregates, which reduces carbon emissions by up to 80%.

Jonite products are also Singapore Green Building Product (SGBP) certified (4 ticks, leader). This means that designers can score additional points under the Functional Systems Criteria (Flooring, Ceiling, Roof, External Wall, Internal Wall and Door systems) and/or Singular Sustainable Products outside of Functional Systems Criteria. This ensures that sustainability is integrated throughout the design and manufacturing process of green building products.

Is there a minimum order for custom items?

No

Jonite Lead Times

Average lead time is 12-14 weeks. Please contact us to confirm lead times as this can vary.

Where are Jonite products made?

Jonite is based in Singapore. SABdrain stocks a limited range. Contact us to find out more.

What are Jonite products made from?

Jonite products are made from reconstituted stone. Created from 95% natural aggregates and advanced hybrid polymers, Jonite products provide a finish which is both luxurious and natural to the touch.

The technical specification of the core material used is: 95% agglomeration of natural stone substrates & mineral oxides formed under a proprietary vacuum and compression process. Composed of a proprietary structural polymer hybrid system of a heterogeneous blend’

The core material is made of 95% natural aggregates like crushed natural granite etc. 5% comprises of a hybrid blend of epoxy resins.

Reinforcements within products are flat steel bars of varying thickness. They are welded into frames and treated with a coat of protection before being incorporated.

How are Jonite products made?

Jonite products are crafted by blending a variety of materials, including natural stone elements and resin as a binding agent, which are then compressed into a mold and reinforced to enhance strength.

Do Jonite products contain silica?

Jonite has worked hard to ensure their products contain less than 1% silica, which has been accepted by SafeWorkNSW. It is rare that a Jonite product will need to be cut on site. If so, it has to be done with correct PPE.

Custom Design Solutions

- Custom Applications

- Tailored load requirements

- Unique colour patterns & aesthetics

- Colours to match project aesthetics

- Range of sizes

The Customisation Process

Collaboration

The design team will have an in-depth discussion with you about your goals and vision as to how Jonite panels can fit into your overall design plans. During this time, Jonite will also ensure that there is both material feasibility and cost efficiency before moving forward.

Conceptualisation

Upon receiving details in terms of the design or application effect you’d like to achieve, the design team will work to conceptualise the ideas. Depending on the time you have set aside for customisation, the team may suggest modifications on Jonite's current existing line of products, or create a brand new design.

Design & testing

Jonite designers will create designs and run stress tests if necessary. During this stage, renderings will be made so that you would be able to visualise the concept fully. Upon receiving your feedback, adjustments can be made to make sure that the designs perfectly encapsulate your vision.

Approval

Once all of the requirements are satisfied, Jonite will seek final sign off before commencing production. At this point in time, Jonite can fully support with any shop drawings required to make sure that all details are captured for the successful completion of your project.

Production

Upon securing the necessary approvals, Jonite will commence with production. Jonite practices Just-In-Time production for all products, and are fully capable of making sure they can deliver within the lead time specified. Experienced sales consultants can help assist to make sure that delivery is on-time for the project.

Customisable Areas

Load Specifications

Colours & Textures

Sizes

Patterns

Open Area

Applications

Sustainability

Made from nature

Made to measure

Others see waste. Jonite see potential

Footprints made friendlier