Why SABdrain?

The SABdrain Advantage

Ease of Assembly

The modular design of our polypropylene channels makes the assembly and installation of the drainage channels easy, thus saving time and money.

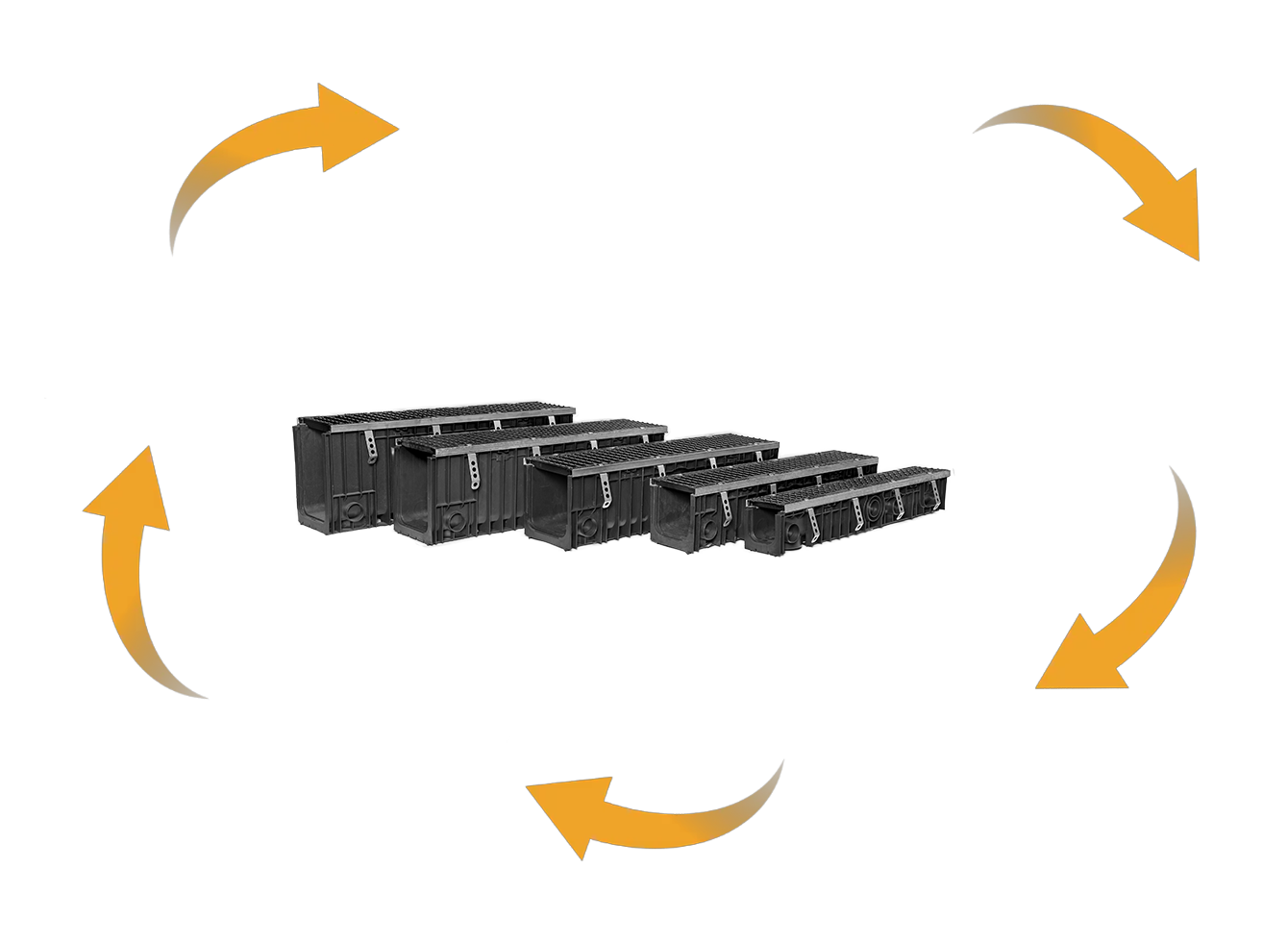

Recyclable

Our products are made from 100% recyclable products that can be used again in the manufacturing process. Therefore protecting for the environment for the future generations.

Hydraulic Performance

The smooth rounded internal surface of the SABdrain water drainage systems creates higher flows rates while allowing a self cleaning action thus avoiding the accumulation of silt deposits.

Chemical Resistance

Due to SABdrain’s superior polypropylene construction, it is able to resist most chemical agents, acids, salts, alkaline, fuels, oils, fats, etc.

High Strength

The advanced construction of the SABdrain drainage channel gives it greater structural rigidity, protecting it from damage during and after installation.

Lightweight

Being manufactured from lightweight materials, SABdrain has the added advantage of being easier to handle, transport, and install.

Anti-Slip

Anti-slip buttons giving the grate a slip resistance surface.

Lock-Down

2 point security lock-down for Anti-Theft peace of mind

Frequently

Asked Questions

Are SABdrain systems easy to install?

Installing SABdrain drainage systems is a simple process due to the click-clack feature on the channels, saving time and labor costs. View detailed information on our installation page.

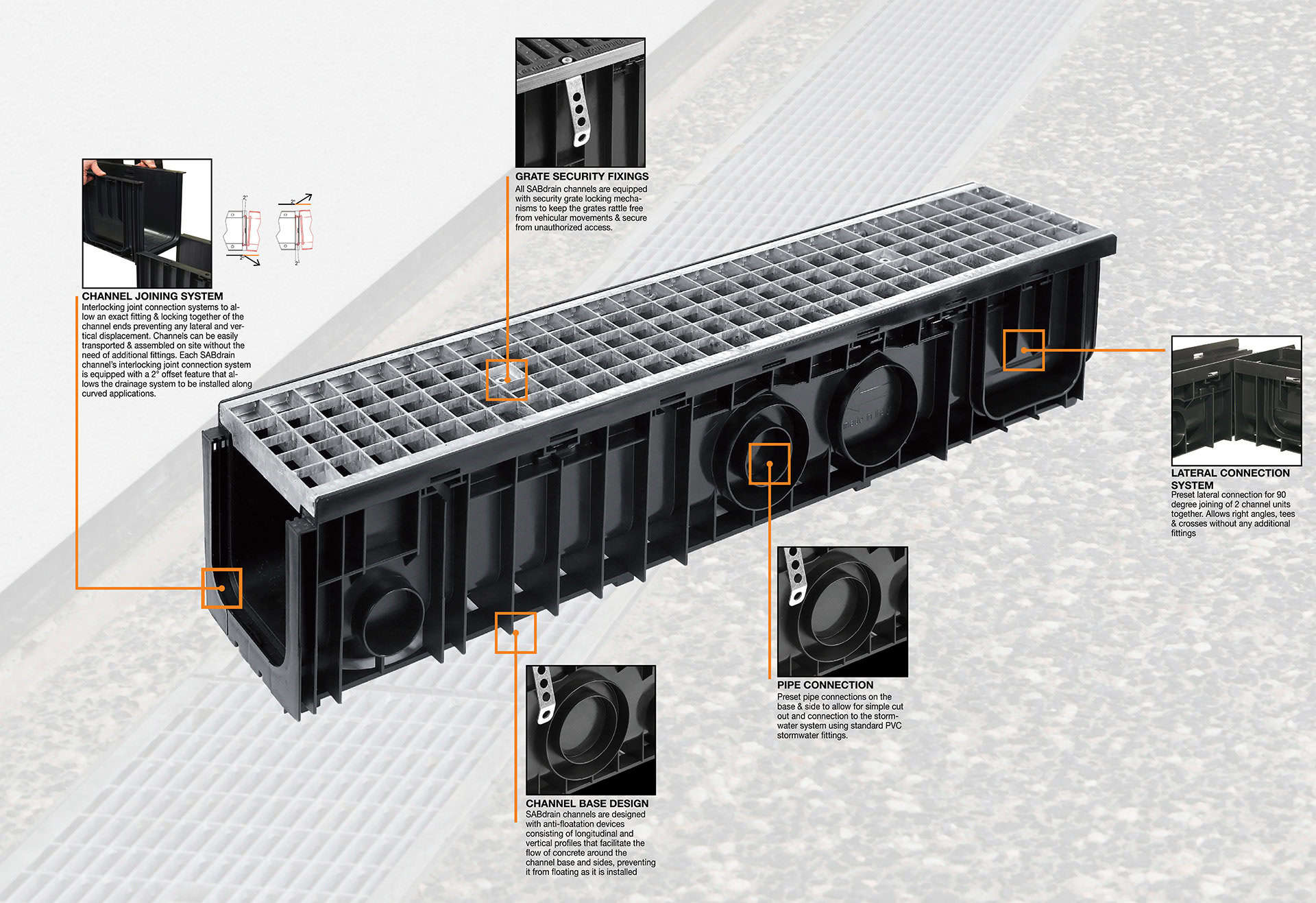

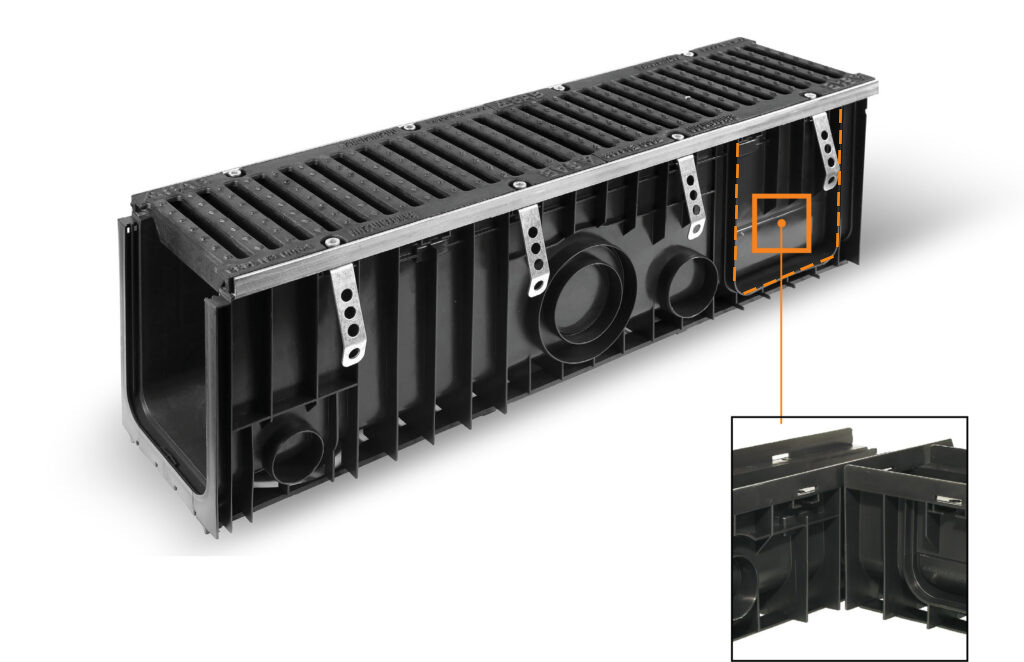

How to create a corner/90 degree angle with SABdrain channels?

SAB channels have preset lateral connection for 90 degree joining of 2 channel units together. Allows right angles, corners, tees & crosses without any additional fittings.

SAB channels have preset lateral connection for 90 degree joining of 2 channel units together. Allows right angles, corners, tees & crosses without any additional fittings.

Cut out the highlighted section above & join the channels.

How to install SABdrain?

SABdrain channels utilise a fast & easy click clack system. See more here.

SABdrain Lead Times

We hold a large amount of stock in our warehouse, which can be shipped out within a day.

What are SABdrain drains made of?

SABdrain channels are manufactured from polypropylene. Grates are available in a range of materials.

Is there an alternative to ACO drainage systems?

Yes, SABdrain drainage systems are an alternative supplier for drainage solutions. SABdrain utilises polypropylene channels over polymer. Polypropylene is a thermoplastic polymer that offers numerous benefits, including high chemical resistance, durability, and flexibility. These qualities make it an ideal choice for drain channel applications in various industries, such as food processing, automotive, and pharmaceutical.

One of the key advantages of polypropylene trench drain channels is their ability to withstand harsh chemicals commonly found in industrial environments. This resistance to corrosion ensures a longer lifespan for the drainage system, reducing maintenance costs and downtime. Additionally, polypropylene channels are lightweight and easy to handle during installation, making the process more efficient and cost-effective.

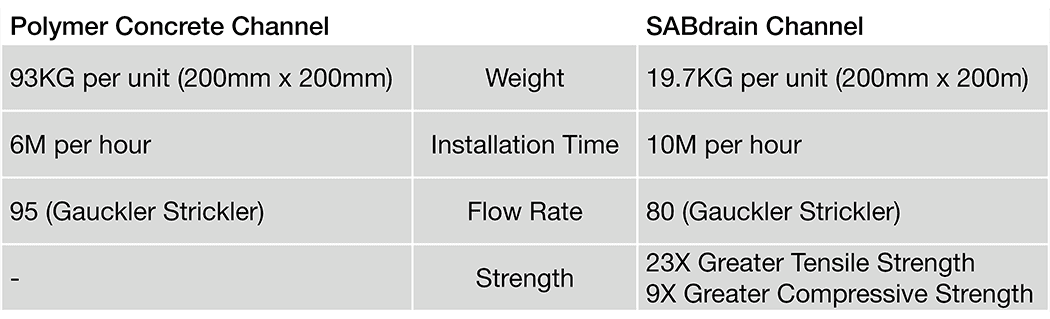

SABdrain VS the Competition

| Polymer Concrete Channel | SABdrain Channel | |

|---|---|---|

| 93KG per unit (200mm x 200mm) | Weight | 19.7KG per unit (200mm x 200m) |

| 6M per hour | Installation Time | 10M per hour |

| 95 (Gauckler Strickler) | Flow Rate | 80 (Gauckler Strickler) |

| - | Strength | 23x Greater Tensile Strength, 9X Greater Compressive Strength |

- High Density Material = Less Weight = Less Breakages

- Precision Assembly

- Preset cut out for corners - no additional fittings needed

- Manufactured & tested to EN1433:2008 & AS3996:2006

- High quality surface for superior hydraulic performance

- Easy to handle, transport & install

What makes SABdrain different?