Polypropylene trench drain channels offer numerous advantages over other materials, making them a superior choice for many applications. Understanding the properties and benefits of polypropylene can help engineers, architects & specifiers make informed decisions when it comes to drainage solutions. This article will explore the advantages of using polypropylene trench drain channels, compare them to other materials, and discuss the potential drawbacks of alternative options. Finally, we will provide guidance on making the switch to polypropylene and highlight why it is the superior choice.

Understanding Polypropylene Trench Drain Channels

Polypropylene is a thermoplastic polymer that is widely used in various industries, including construction and drainage systems. It is a versatile material known for its durability, flexibility, and chemical resistance. These properties make it highly suitable for trench drain channels.

When it comes to outdoor drainage systems, polypropylene trench drain channels stand out as a top choice due to their exceptional performance and longevity. These channels are designed to effectively manage water runoff in various settings, from residential driveways to industrial facilities. The use of polypropylene ensures that the channels can withstand harsh weather conditions, heavy loads, and exposure to chemicals without compromising their structural integrity.

What is Polypropylene?

Polypropylene is a type of plastic that is derived from propylene monomers. It is known for its excellent physical properties, including high melting point, low coefficient of friction, and resistance to chemicals and UV radiation. These characteristics make polypropylene an ideal choice for outdoor drainage applications.

In addition to its exceptional durability, polypropylene is also a sustainable material, making it an environmentally friendly option for trench drain channels. Its recyclability and long lifespan contribute to reducing the overall environmental impact of drainage systems, aligning with modern sustainability practices.

Structure & Design of Polypropylene Trench Drain Channels

Polypropylene trench drain channels are typically designed with a structurally reinforced frame that provides strength and stability. The unique composition of polypropylene allows for the creation of intricate channel patterns that facilitate efficient water flow and prevent clogs. Additionally, these channels are lightweight and easy to install, reducing labour and transportation costs.

Furthermore, the design flexibility of polypropylene trench drain channels allows for customisation to suit specific project requirements. Whether it's creating sloped channels for optimal water flow or incorporating grates for debris filtration, polypropylene channels offer versatility in design options. This adaptability ensures that drainage systems can be tailored to effectively address varying needs across different applications and environments.

Comparing Drain Channel Materials

Before delving into the advantages of polypropylene trench drain channels, it is essential to compare them to other commonly used materials.

Common Materials Used in Trench Drain Channels

Traditionally, drain channels have been made from materials such as metal and concrete. While these materials have been widely used, they come with their own set of limitations.

Another material that has gained popularity in recent years is fibreglass. Fibreglass trench drain channels offer a lightweight alternative to traditional materials while providing excellent durability and resistance to corrosion. This makes them ideal for various applications, including industrial settings and commercial facilities.

Polymer Concrete Channel

Stainless Steel Channel

Fibreglass Channel

Polypropylene vs Other Materials: A Detailed Comparison

When compared to metal drain channels, polypropylene offers several advantages. Metal channels are susceptible to corrosion, which can compromise their structural integrity over time. Polypropylene, on the other hand, is corrosion-resistant and does not require regular maintenance.

Additionally, polypropylene trench drain channels are highly resistant to chemicals, making them suitable for environments where exposure to harsh substances is common. This chemical resistance ensures the longevity of the drainage system and reduces the need for frequent replacements.

Concrete drain channels, while durable, can be heavy and challenging to install. Especially in hard to reach areas. Polypropylene trench drain channels are lightweight, making them easier to handle and reducing the risk of accidents during installation.

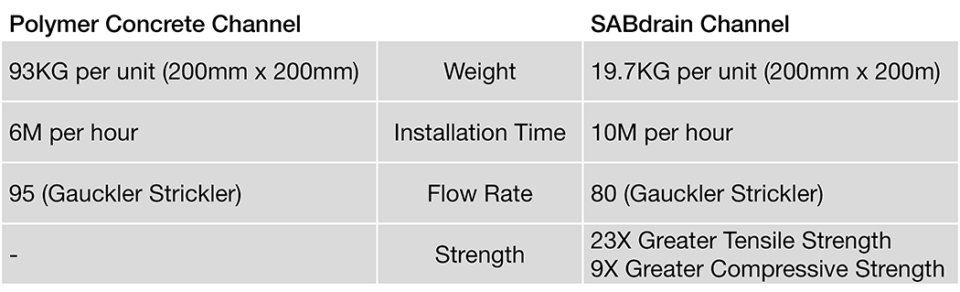

| Polymer Concrete Channel | SABdrain Channel | |

|---|---|---|

| 93KG per unit (200mm x 200mm) | Weight | 19.7KG per unit (200mm x 200m) |

| 6M per hour | Installation Time | 10M per hour |

| 95 (Gauckler Strickler) | Flow Rate | 80 (Gauckler Strickler) |

| - | Strength | 23x Greater Tensile Strength, 9X Greater Compressive Strength |

- High Density Material = Less Weight = Less Breakages

- Precision Assembly

- Preset cut out for corners - no additional fittings needed

- Manufactured & tested to EN1433:2008 & AS3996:2006

- High quality surface for superior hydraulic performance

- Easy to handle, transport & install

The Benefits of Polypropylene

Now that we have explored the limitations of other materials, let us delve into the specific benefits of polypropylene trench drain channels.

Polypropylene is a versatile and reliable material that offers a multitude of benefits for various applications. Its exceptional durability is one of its standout features, making it ideal for withstanding harsh conditions in both residential and commercial settings. Whether exposed to extreme weather, heavy loads, or corrosive chemicals, polypropylene trench drain channels maintain their structural integrity, ensuring long-term performance and longevity.

Durability & Longevity of Polypropylene

Polypropylene is known for its exceptional durability, making it suitable for both residential and commercial applications. It can withstand extreme temperatures, heavy loads, and the corrosive effects of chemicals, ensuring long-term performance and longevity.

Moreover, polypropylene's resistance to rust, corrosion, and degradation over time sets it apart from other materials, providing a reliable drainage solution that requires minimal upkeep. This durability translates to cost savings over the lifespan of the trench drain channels, as they do not need frequent repairs or replacements, contributing to their overall cost-effectiveness.

Cost Effectiveness of Polypropylene Trench Drain Channels

One of the significant advantages of using polypropylene trench drain channels is cost-effectiveness. Compared to alternative materials, such as metal or concrete, polypropylene channels are more affordable. In addition to lower upfront costs, they require minimal maintenance and offer long service life, resulting in reduced overall expenses.

Furthermore, the lightweight nature of polypropylene makes it easier and more cost-effective to transport and install, saving both time and money during construction or renovation projects. Its versatility allows for customisation and easy modifications on-site, reducing labour costs and potential disruptions to the project timeline.

Environmental Impact

Another notable benefit of polypropylene trench drain channels is their minimal impact on the environment. Polypropylene is fully recyclable, allowing for easy disposal and reducing waste. Moreover, the manufacturing process of polypropylene involves lower energy consumption and carbon emissions compared to other materials, making it an eco-friendly choice.

By choosing polypropylene trench drain channels, you are not only investing in a durable and cost-effective drainage solution but also making a sustainable choice that aligns with environmental stewardship. The recyclability and energy-efficient production of polypropylene contribute to a greener construction industry, promoting responsible resource management and reducing the ecological footprint of infrastructure projects.

Potential Drawbacks of Other Drain Channel Materials

While polypropylene offers many advantages, it is essential to consider the potential drawbacks of alternative drain channel materials.

When exploring different drain channel materials, it's crucial to delve into the specific challenges associated with each option. Understanding these drawbacks can help in making an informed decision that aligns with your project requirements and long-term goals.

Issues with Metal Drain Channels

Metal drain channels, such as steel or aluminium, can be prone to rust and corrosion over time. This can lead to structural damage and compromised functionality. Regular maintenance and protective coatings are required to mitigate this risk, increasing both time and cost.

In regions with high humidity or exposure to corrosive substances, the lifespan of metal drain channels may be significantly reduced. Factors like water chemistry and environmental conditions play a crucial role in determining the maintenance needs of metal channels, making them less ideal for certain applications.

Problems with Concrete Drain Channels

Concrete drain channels are durable but can be heavy and difficult to handle during installation. They also require precise site preparation and skilled labour to ensure proper alignment and prevent leakage. Additionally, concrete channels may develop cracks or deteriorate over time, requiring expensive repairs or replacement.

Despite their robust nature, concrete drain channels are susceptible to environmental factors like freeze-thaw cycles and chemical exposure, which can impact their structural integrity. Proper installation techniques and regular inspections are essential to mitigate these risks and prolong the lifespan of concrete channels in demanding environments.

Making the Switch to Polypropylene

Considering the advantages and drawbacks of different drain channel materials, many professionals are opting to make the switch to polypropylene. Polypropylene is a thermoplastic polymer that offers numerous benefits, including high chemical resistance, durability, and flexibility. These qualities make it an ideal choice for drain channel applications in various industries, such as food processing, automotive, and pharmaceutical.

One of the key advantages of polypropylene trench drain channels is their ability to withstand harsh chemicals commonly found in industrial environments. This resistance to corrosion ensures a longer lifespan for the drainage system, reducing maintenance costs and downtime. Additionally, polypropylene channels are lightweight and easy to handle during installation, making the process more efficient and cost-effective.

Considerations When Switching Materials

Switching from traditional materials to polypropylene trench drain channels requires careful consideration. Factors to assess include site conditions, load requirements, and installation processes. Engaging with experienced drainage professionals can help ensure a smooth transition. It is essential to evaluate the specific needs of the project and select the appropriate polypropylene channel design to maximize performance and longevity.

Steps to Transition to Polypropylene Trench Drain Channels

The transition to polypropylene trench drain channels involves several steps. Firstly, a thorough analysis of the existing drainage system is conducted, identifying potential improvement areas. Next, the optimal size, shape, and design of polypropylene channels are determined to meet specific project requirements. Careful planning and coordination are essential to ensure a seamless transition without disrupting operations. Finally, the installation process involves removal of the old channels and precise placement of the new polypropylene channels, adhering to industry standards and best practices.

Why Polypropylene is the Superior Choice

In conclusion, polypropylene trench drain channels offer significant advantages over other materials. They provide durability, cost-effectiveness, and minimal environmental impact. By avoiding the potential drawbacks of metal and concrete drain channels, professionals can enhance the overall performance and longevity of drainage systems. Consider making the switch to polypropylene trench drain channels for your next project and experience the numerous benefits they offer.