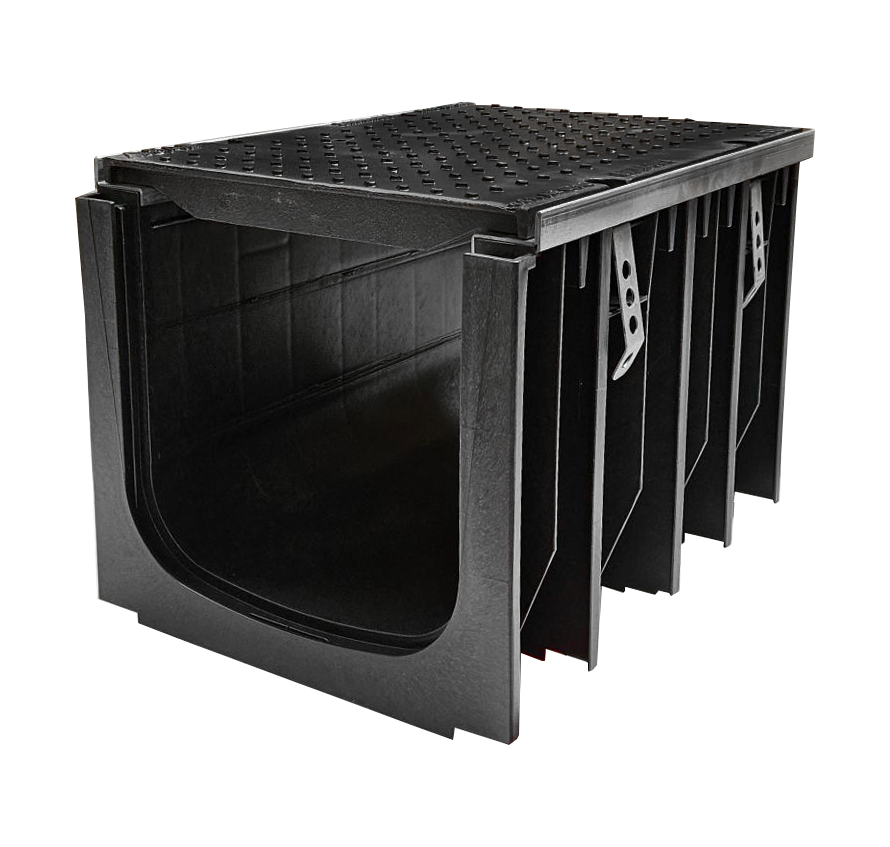

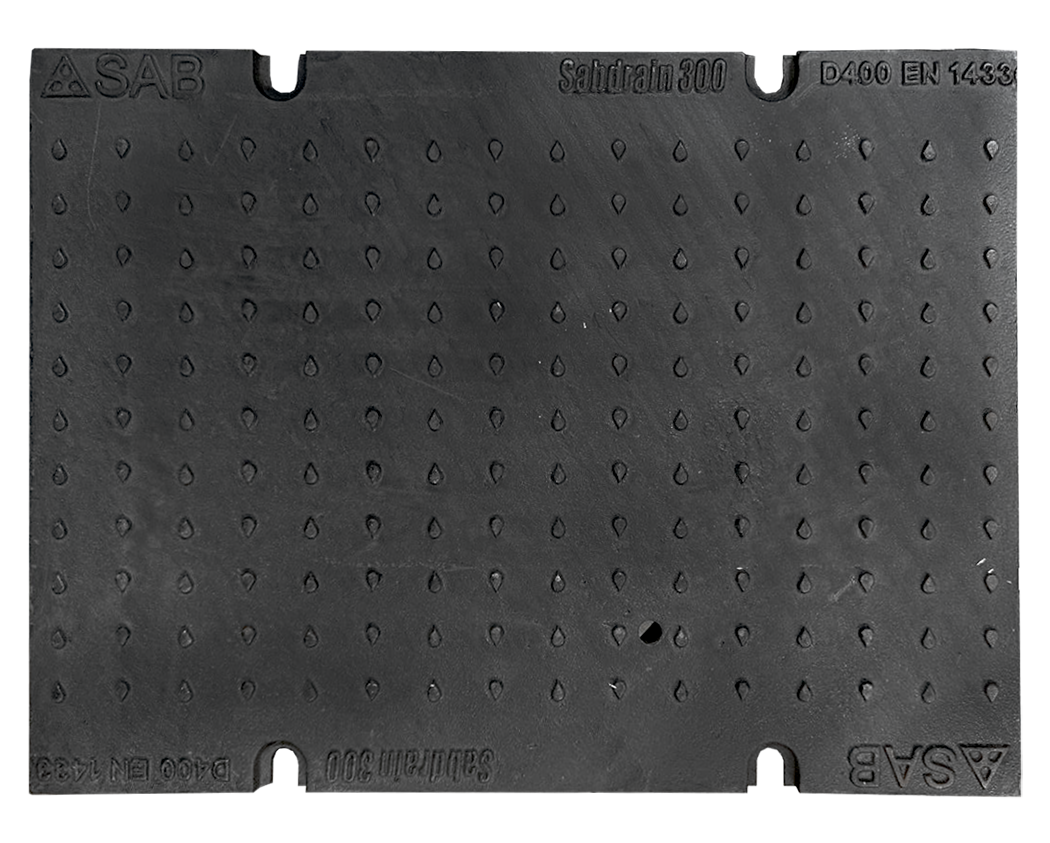

Class E rated solid ductile cast iron covers with SABdrain polypropylene channels. Carefully engineered to provide a reliable solution where a solid cover is required. Undergoing stringent load testing to meet the standards of AS3996, the covers are rated Class E; suitable for heavy commercial traffic. The assembly is meticulously engineered to create a secure seal, preventing any rocking motion when subjected to passing traffic. The rattle-free lockdown feature further enhances the reliability of these covers, ensuring long-lasting performance in environments where durability is crucial. SABdrain 800 cast iron covers & channels are a practical choice for areas demanding a robust, long lasting system.

800 Grande

Drains

Drains

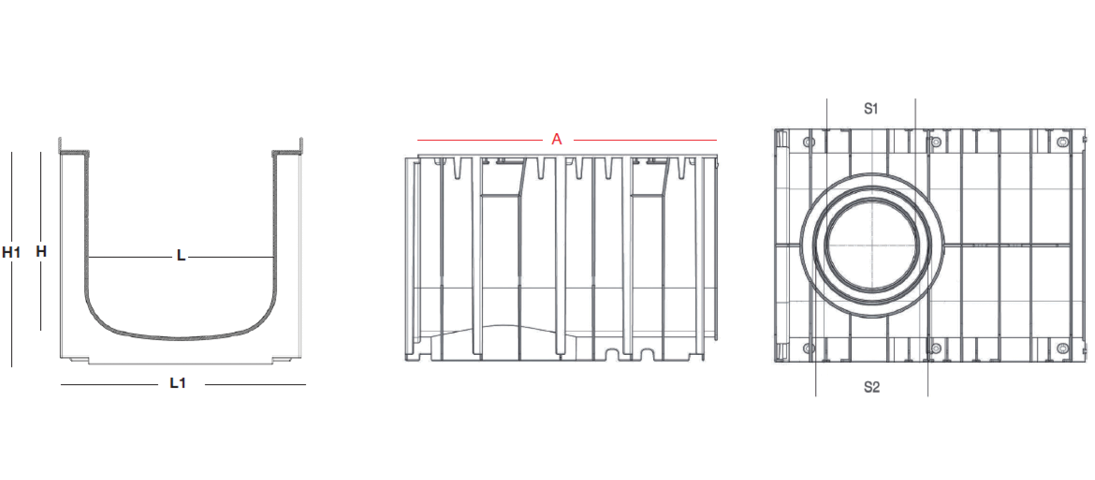

| Product Code | L | H | L1 | H1 | D1 | D2 | D3 | D4 | D5 | S1 | S2 | A | KG |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DR800300200 | 300 | 200 | 390 | 260 | - | - | - | - | - | 160 | 200 | 500 | 18.8 |

| DR800300300 | 300 | 300 | 390 | 360 | - | - | - | - | - | 160 | 200 | 500 | 19.2 |

Grates

Grates

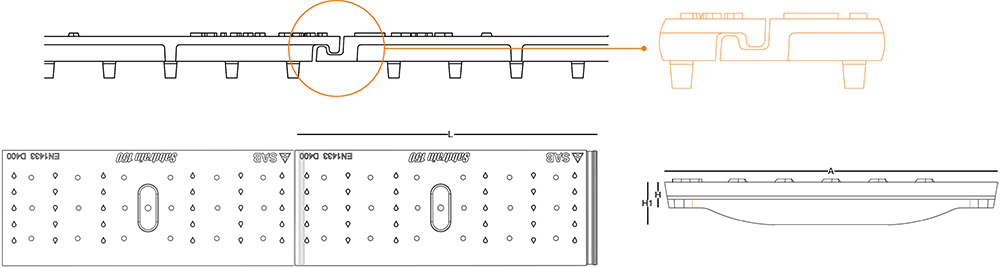

| Code | Material | Drain Cm² | A | H | H1 | L | F | Load Class | KG |

|---|---|---|---|---|---|---|---|---|---|

| DR800PLATE300 | Cast Iron | - | 376 | 20 | 40 | 500 | - | E | 13.8 |

Frequently

Asked Questions

What is the grande series?

The SABdrain grande series simply refers to any product where the width of the channel is larger than 300mm internally

Will cast iron grates rust?

Like most metals, cast iron goes through a natural oxidation process, resulting in an outer protective coating known as rust. This process is called Patina. Patina is a naturally occurring process and shouldn’t be confused with corrosive rust.

The two conditions that cause cast iron to rust are:

- Moisture (Cast iron will begin to patina when the relative humidity exceeds about 64%.)

- Oxygen

Factors that accelerate rusting:

- Carbon Dioxide

- Acids

- Impurities

Like most metals, cast iron goes through a natural oxidation process, resulting in an outer protective coating known as rust. This process is called Patina.

Patina is a naturally occurring process and shouldn’t be confused with corrosive rust. Patina is good for iron as it provides a protective layer. A metals patina is a thin layer of oxides on the metal that acts to slow down further corrosion. Therefore patina on cast iron grates does not harm the structural integrity. This rust layer shields the cast iron from further oxidation. Think of rust as a corroded armour that protects against additional corrosion. This property allows iron to remain strong & intact for several decades. Unlike steel, cast iron is durable and will not flake. The patination of cast iron grates is predictable, and the duration of each stage depends on local moisture conditions, foot traffic, foreign substances etc.

Once the oxidation process begins, cast iron will turn a bright orange and then fade to a chocolate brown, similar to the colour of manhole covers.

Rust cannot be prevented but the process may be slowed by introducing a buffer material between the iron and atmosphere. Linseed oil can be applied to the grates prior to installation. Another common practice is to spray or powder coat the grates. This coating must be reapplied whenever there is chipping to maintain rust protection.

Cleaning/Maintenance

In order to obtain better performance from drainage channels, it is necessary to properly maintain and clean the channels to prevent them from getting clogged with soil, leaves or other sediment, thus rendering drainage ineffective.

Read more here.

How to install SABdrain?

SABdrain channels utilise a fast & easy click clack system. See more here.

What drain should I install?

This depends on a lot of factors such as desired aesthetic, what load class you need & where is it being installed. Check how much water the area will receive, has it got a slope? Is it near your pool? Do you live near saltwater?

Use our handy product finder or contact us.