Drainage grates play a crucial role in maintaining the proper functioning of a drainage system. They prevent debris, trash, and other materials from clogging the drain, allowing water to flow freely. However, over time, drainage grates can become damaged or broken due to wear and tear, weather conditions, or even vandalism. If left unrepaired, broken drainage grates can cause flooding, property damage, and even pose a safety hazard. To ensure that your drainage system remains efficient and effective, it’s important to promptly replace broken drainage grates. In this article, we’ll discuss the steps you can take to correctly identify and the process of replacing broken grates to ensure that your drainage system is operating at optimal levels.

Why do grates break?

Time

As time passes, the edges of the trench drain can deteriorate, channels may collapse, and grates can loosen, leading to the failure of parts of or the entire drainage system.

Poor Maintenance

To ensure consistent and effective drainage, conducting annual maintenance of your trench drain system is essential. These drainage systems are exposed to harsh environmental conditions throughout the year, causing gradual wear and tear. Without proper maintenance, the drainage system is at risk of failure. If debris is left unattended, it can accumulate and obstruct the flow of water, leading to unwanted water runoff in undesired locations.

Improper Specification

When selecting a trench drain system, it’s crucial to consider the specific requirements of your application as they are designed for particular uses. One key factor to evaluate is the type of traffic that will pass over the grates. It’s important to choose a trench drain that can handle the weight load or Load Class of the heaviest traffic to prevent system failure and potential property damage, which can lead to expensive repairs.

Moreover, the dimensions of the trench drain system determine its water flow capacity. To ensure efficient water drainage, it’s necessary to specify a trench drain system that is large enough to handle the expected water volume in the area. Installing a drainage system that is too small can result in flooding, making it another common mistake to avoid.

Replacing Broken Grates

Replacing broken drainage grates can be a challenging task, particularly when attempting to match the existing grate. Identifying the correct size and style of the broken grate can be difficult, as it may have been manufactured by a company that is no longer in business or no longer produces that specific model. Additionally, even if the manufacturer is still operational, it can be challenging to determine the original manufacturer of the grate. In many cases, the grate may have been customised or modified, making it even more difficult to locate a matching replacement. As a result, it’s important to have a thorough understanding of the grate’s specifications and design before attempting to replace it to ensure the correct replacement is installed.

Measuring

The first step you need to take when looking for replacement grates is to measure the existing channel & grate. There are many different sizes, shapes and profiles of grates & each measurement you take is important in determining whether your new grate will sit in the channel correctly.

Grate

- Width at top of grate (take note of whether the grate has an edge that covers the side of the channel)

- Height of grate

- Width of underside of grate

- Height of underside of grate

- Grate length

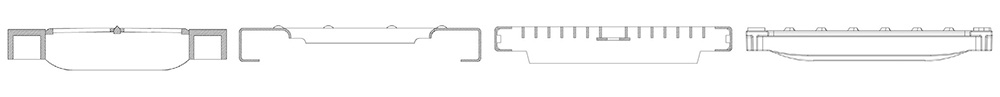

note: not all grates will have the above characteristics to measure. See below image for examples of types of grate profiles

Channel

- Internal Width

- Internal Height

- External Width

- External Height (if accessible)

- Edge of channel

Identifying what type of channel is used with the grate will also be helpful. Polymer & polypropylene/plastic are common. Check the channel for damage as well.

Identifying The Grate Material

Identifying the material of a drainage grate is an important step when replacing or repairing it. One way to identify the material is through a visual inspection. Common materials for drainage grates include cast iron, steel, aluminium, and plastic. Cast iron is the most common material used for drainage grates due to its durability and resistance to corrosion. Steel is also a popular material and is often used for its strength and ability to handle heavy loads. Aluminium is lightweight and resistant to corrosion, making it an excellent choice for outdoor environments. Plastic grates are also available, and while they are less durable than metal grates, they are lightweight and easy to install. To determine the material of a drainage grate, you can also consult the manufacturer’s specifications or use a magnet to test for ferrous materials such as iron or steel.

Manufacturers Mark

Most grates will have a manufacturers mark on it that will help you determine the grates origins.

Replacing Broken Grates : Your Options

If you have identified the original manufacturer of the drainage grates, the next step is to contact them to purchase the replacement grates. The manufacturer can provide information on the specifications and requirements of the grates, ensuring that you get the exact match for your drainage system. However, if the original manufacturer is no longer in business or does not produce that specific model, it can be challenging to find a matching replacement. In this case, you may be able to find a similar grate using the measurements taken or consult with a plumber. They can recommend suitable alternatives or suggest custom solutions to ensure proper functioning of the drainage system. It is important to avoid using mismatched or poorly fitting grates, as they can cause uneven water flow, blockages, and potential damage to the system.