Frequently Asked Questions

Refine our faqs to a category:

How to stop driveway flooding?

Sloped driveways and heavy rainfall make for an unfortunate combination and can become a dangerous slipping hazard. Plus, excess water can end up flooding your yard, garage or seeping into the foundation of your house. Trench drains are the most common type of driveway drainage solution. These are long channels that run across the width of the driveway. Water flows into the drain, which can empty into additional drainage elements around your home.

What can I customize on the Jonite tree grates?

Along with the usual suspects of colour and design customization across most of Jonite products, they can also customize the tree grates’ configurations. For example, if you require a specific shape or an unusually large area, Jonite can plan and design tree grate configurations to fit your needs. Features like expandability, lockability, and light ports can also be customized.

Is there a minimum order quantity for custom tree grates?

No. Jonite is more than happy to customize one set of tree grates.

What are the different types of surface drainage?

Different types of surface drainage solutions includes in-line pits, open swales or grated trench drainage. Cost comparisons have shown modular trench drains to have lower total installed costs when labour, excavation, pipework, grading etc., are taken into account. Furthermore, heavier materials such as polymer concrete will drive up labour and transport costs.

Discover the advantages of using polypropylene instead of polymer.

Will stainless steel rust?

Despite its anti-rust properties, you may see some stainless steel that appears to have rust on the surface. This is known as tea staining. Tea staining is rust forming on the surface of stainless steel, causing a discolouration similar to a tea stain. It may not look appealing, tea staining is only cosmetic and does not affect the functionality or integrity of the stainless steel. Regular cleaning and maintenance with a mild soap and water solution can remedy the discolouration.

Can Jonite tree grates be expanded for growing trees?

Not all tree species need this feature, but if you do, Jonite has selected models like their ADA Collection, which offers up to 4 different inner diameters (390/460/530/600mm). Should you need even more expandability, some models like the Square Slots can expand even beyond that. Contact us for better advice on this.

Are Jonite Breeze Blocks suitable for outdoor applications?

Certainly! Jonite Breeze Blocks aren’t merely appropriate for exterior use, but they thrive under these conditions. Their special material makeup allows them to resist even the most severe weather and temperature conditions. They also feature self cleaning properties, making them significantly more durable than traditional concrete breeze blocks.

How to clean drains?

Remove any large pieces of debris. Drainage channels can be cleaned with a broom or shovel. Persistent dirt can be cleaned with a high pressure cleaner (jet pressure up to 120 bar), running the cleaning water along the entire length of channel. Ensure all sediment within the channel is loosened and rinsed down to the plumbing/sump pit. The discharge points must be cleaned & ensure pipework is draining effectively.

More information here.

What is polypropylene?

Polypropylene is a thermoplastic polymer that offers numerous benefits, including high chemical resistance, durability, and flexibility. These qualities make it an ideal choice for drain channel applications in various industries, such as food processing, automotive, and pharmaceutical.

What is the life cycle of Jonite products?

The general life cycle of Jonite products is minimally 30 years or more

How durable are Jonite pool grates near chlorine pools or fountains?

Jonite pool grates are specially designed to be resistant to chlorine. On top of that, it contains reinforcements made of a non-ferrous composite material which prevents it from rusting but at the same time, providing excellent compressive strength while being lightweight.

Can you drive over a SABdrain system?

Yes. SABdrain has a range of trafficable drainage systems, rated from Class B – Class G

Can Jonite design the support if I were to customize the panels for the bench?

Jonite can design a simple panel support system. However, please take note that any mounting or fixtures will not be included in the design.

How to keep water out of garage?

Sloped driveways and heavy rainfall make for an unfortunate combination and can become a dangerous slipping hazard. Plus, excess water can end up flooding your yard, garage or seeping into the foundation of your house. Trench drains are the most common type of driveway drainage solution. These are long channels that run across the width of the driveway. Water flows into the drain, which can empty into additional drainage elements around your home.

How to improve driveway drainage?

Trench drains are the most common type of driveway drainage solution. These are long channels that run across the width of the driveway. Water flows into the drain, which can empty into additional drainage elements around your home.

Why is surface drainage important?

Standing or ponding water in and around buildings or on roads can cause severe structural damage to foundations, building materials and other structures so it’s important to utilise surface drainage solutions to divert it quickly and efficiently. Surface drainage is also crucial to help prevent hydroplaning on roads, highways, bridges and airport runways.

Effective handling and transporting away stormwater during, and after storms is a vital element in facility and road construction planning.

Discover the SABdrain advantages – click here

How sustainable are stone trench grates compared to traditional trench grating?

Jonite use at least 30% recycled aggregates in their stone grating products, which reduces carbon emissions by up to 80%. All Jonite decorative grating is Singapore Green Building Product (SGBP) certified (4 ticks, leader). This means when you choose Jonite stone trench grates, you can score additional points under the Functional Systems Criteria (Flooring, Ceiling, Roof, External Wall, Internal Wall and Door systems) and/or Singular Sustainable Products outside of Functional Systems Criteria.

Do plastic channels warp in concrete?

Once polypropylene channels are encased in concrete, they are rigid. Warping or bending is due to incorrect installation, such as concreting with no grate installed.

How to clear a clogged drain with standing water?

Remove any large pieces of debris. Drainage channels can be cleaned with a broom or shovel. Persistent dirt can be cleaned with a high pressure cleaner (jet pressure up to 120 bar), running the cleaning water along the entire length of channel. Ensure all sediment within the channel is loosened and rinsed down to the plumbing/sump pit. The discharge points must be cleaned & ensure pipework is draining effectively.

More information here.

What drainage channel material should I select?

When compared to metal drain channels, polypropylene offers several advantages. Metal channels are susceptible to corrosion, which can compromise their structural integrity over time. Polypropylene, on the other hand, is corrosion-resistant and does not require regular maintenance.

Additionally, polypropylene trench drain channels are highly resistant to chemicals, making them suitable for environments where exposure to harsh substances is common. This chemical resistance ensures the longevity of the drainage system and reduces the need for frequent replacements.

Concrete drain channels, while durable, can be heavy and challenging to install. Especially in hard to reach areas. Polypropylene trench drain channels are lightweight, making them easier to handle and reducing the risk of accidents during installation.

I am thinking of customizing a Jonite product? Where do I start?

Jonite has a transparent step-by-step process page on their website to give you an idea. Contact us today to start your process.

How much does a drainage system cost?

The cost of a drainage system depends on the materials used, and the size. A system with a wide stainless steel grate will be more expensive than the same size with a polypropylene system. Reducing the width of your grate will help reduce costs.

SABdrain channels have a greater flow rate (up to 18% faster), therefore reducing the size has less impact on efficiency.

Are Jonite tree grates compliant with the American Disabilities Act (ADA)?

Some of our models are ADA compliant. Should you prefer a particular design, Jonite can modify and customize the grates to be ADA compliant.

What types of drains are used in residential applications?

There are a number of drainage solutions for residential areas such as driveways, gardens, balconies, pool areas, patios and more. Materials, sizing and grates will vary project to project.

For more information, click here.

Are pool grates necessary for my pool?

Pool grates may not be necessary for all types of pools. However, for overflow pools, they significantly reduce the splash generated from the pool when in use.

What trench drains are used in a sea port environment?

Wharves and docks provide a challenging environment due to extreme dynamic forces and corrosive surroundings. Installation must be carefully planned to minimize interruptions to workflow.

SABdrain has a range of drainage solutions suitable to be used in port and wharf environments. Discover more here.

Polymer drainage channels are better suited for commercial environments

This is something commonly believed in the drainage industry, and it’s a myth. Polypropylene channels bring the strength, chemical resistance and durability that commercial environments actually demand. Lightweight, easy to install, and built to last – they outperform traditional polymer channels in real-world conditions.

How to clear an outdoor drain?

Remove any large pieces of debris. Drainage channels can be cleaned with a broom or shovel. Persistent dirt can be cleaned with a high pressure cleaner (jet pressure up to 120 bar), running the cleaning water along the entire length of channel. Ensure all sediment within the channel is loosened and rinsed down to the plumbing/sump pit. The discharge points must be cleaned & ensure pipework is draining effectively.

More information here.

What is the difference between 304 and 316 stainless? Which should I use?

A 304 stainless steel drainage grate and a 316 stainless steel drainage grate differ primarily in their composition and corrosion resistance. 304 stainless steel is a versatile and commonly used grade known for its excellent corrosion resistance in various environments, making it suitable for many applications.

316 stainless steel contains higher levels of chromium and additional elements like molybdenum, which enhance its resistance to corrosion, particularly in harsher conditions such as marine environments or exposure to chloride-containing solutions.

Within a kilometre of breaking surf, 316 stainless is recommended to be utilised. Additional care will still need to be undertaken to prevent tea staining. See more about the maintenance of stainless steel here.

Can Jonite Breeze Blocks be designed to a specific open area for better ventilation?

Absolutely, Jonite is capable of tailoring a breeze block to match your unique open area needs. In contrast to other Jonite products, breeze blocks are less reliant on load requirements, giving us increased flexibility in open area customization.

How well do Jonite trench grates hold up under extreme weather?

Specified in projects all over the world including Dubai, Singapore and various states in the United States, Jonite has been used in the hottest, coldest and most humid places in the world with no known problems.

Do Jonite products contain silica?

Jonite has worked hard to ensure their products contain less than 1% silica, which has been accepted by SafeWorkNSW. It is rare that a Jonite product will need to be cut on site. If so, it has to be done with correct PPE.

What removes tea stains from stainless steel?

White vinegar is effective for helping remove or reduce tea staining from stainless steel.

Learn more about the process here.

What is the grande series?

The SABdrain grande series simply refers to any product where the width of the channel is larger than 300mm internally

Internal/External Measurements

All SABdrain channel measurements are internal.

What grates are suitable for slope drain?

SABdrain galvanised, polypropylene, cast iron and stainless grates in widths of 100mm, 150mm, 200mm, 250mm, 300mm & 500mm.

What is polypropylene?

Polypropylene is a type of plastic that is derived from propylene monomers. It is known for its excellent physical properties, including high melting point, low coefficient of friction, and resistance to chemicals and UV radiation. These characteristics make polypropylene an ideal choice for outdoor drainage applications.

In addition to its exceptional durability, polypropylene is also a sustainable material, making it an environmentally friendly option for trench drain channels. Its recyclability and long lifespan contribute to reducing the overall environmental impact of drainage systems, aligning with modern sustainability practices.

What is the difference between a sump cover and trench grate?

The most significant difference is that a sump cover is designed for point drainage systems while trench grates are used for linear drain systems. In most cases, point drainage is more inexpensive as you use fewer grates.

Is Jonite sustainable?

Jonite is on a mission to lead the way towards a greener future. This is why everything Jonite does starts with sustainability in mind. All Jonite products are proudly made of at least 30% recycled materials. Unused products don’t go in the trash. Steel and stone that meet their strict requirements are recycled so they can be used again as raw materials.

Learn more here.

Can sump covers be used as replacements for trench grates?

This depends on several factors such as gradient and drainage requirements of a site. For certain cases which requires a massive dispersion of water from a wider area, linear drains might be more suitable. Sump covers can also be used in conjunction with trench grates for more drainage.

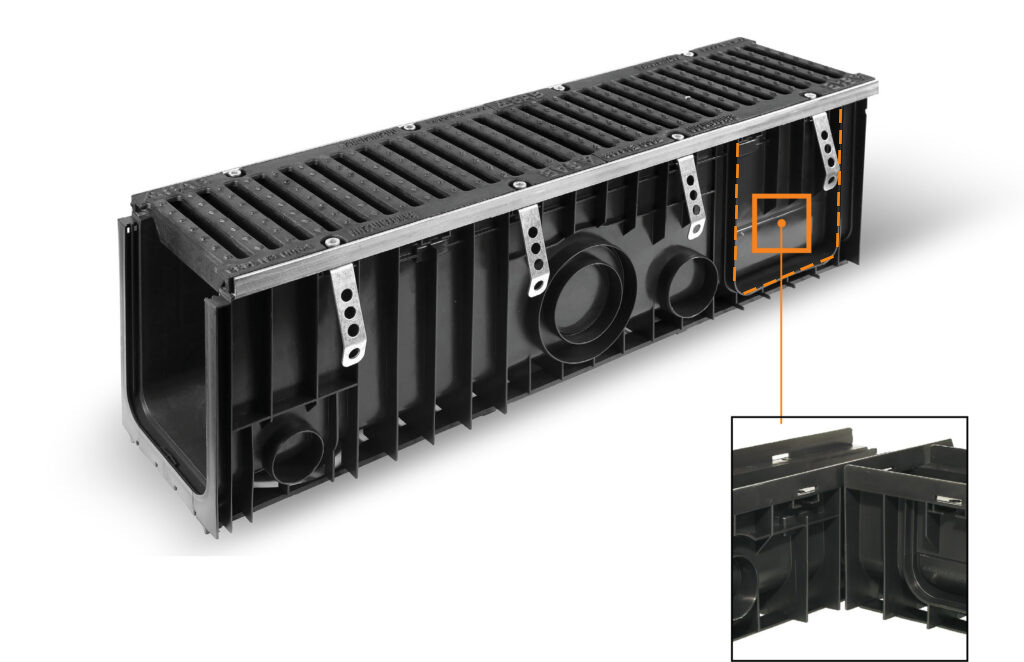

How to create a corner/90 degree angle with SABdrain channels?

SAB channels have preset lateral connection for 90 degree joining of 2 channel units together. Allows right angles, corners, tees & crosses without any additional fittings.

SAB channels have preset lateral connection for 90 degree joining of 2 channel units together. Allows right angles, corners, tees & crosses without any additional fittings.

Cut out the highlighted section above & join the channels.

How wide or deep does my trench drain need to be?

This will vary based on slopes, rainfall, weather patterns and location of the drain.

Use our partners tool here to design your system, or contact us for assistance.

Is it cheaper to form channels/use grate and frame?

It may be tempting, however labor costs can quickly increase with the time spent forming up the channel. Many grates are also designed to be locked into channels.

Is there an alternative to Polycrete drains?

Yes, SABdrain drainage systems are an alternative supplier for drainage solutions. SABdrain utilises polypropylene channels over polymer. Polypropylene is a thermoplastic polymer that offers numerous benefits, including high chemical resistance, durability, and flexibility. These qualities make it an ideal choice for drain channel applications in various industries, such as food processing, automotive, and pharmaceutical.

One of the key advantages of polypropylene trench drain channels is their ability to withstand harsh chemicals commonly found in industrial environments. This resistance to corrosion ensures a longer lifespan for the drainage system, reducing maintenance costs and downtime. Additionally, polypropylene channels are lightweight and easy to handle during installation, making the process more efficient and cost-effective.

How often do I need to maintain/clean my trench drain system?

It is essential to complete regular stormwater drain maintenance to ensure a safe environment on your property. When drainage systems overflow, it creates unsafe conditions and potentially costly damage. Here’s a guide to maintaining & the upkeep of stormwater drains.

Are SABdrain systems easy to install?

Installing SABdrain drainage systems is a simple process due to the click-clack feature on the channels, saving time and labor costs. View detailed information on our installation page.

What are Jonite products made from?

Jonite products are made from reconstituted stone. Created from 95% natural aggregates and advanced hybrid polymers, Jonite products provide a finish which is both luxurious and natural to the touch.

The technical specification of the core material used is: 95% agglomeration of natural stone substrates & mineral oxides formed under a proprietary vacuum and compression process. Composed of a proprietary structural polymer hybrid system of a heterogeneous blend’

The core material is made of 95% natural aggregates like crushed natural granite etc. 5% comprises of a hybrid blend of epoxy resins.

Reinforcements within products are flat steel bars of varying thickness. They are welded into frames and treated with a coat of protection before being incorporated.

What are the different load standards for grates?

AS3996 is the Australian standard that provides the appropriate load rating based on weight, location and other environmental factors. It is the responsibility of the designer/specifier to ensure an appropriate class is selected and/or specified. Specifics of the installation location should be taken into consideration when selecting the right cover or grate. The speed of traffic, wheel type and the physical position (turning area) should all be assessed.

Standards vary around the globe, however AS3996, EN1433 and EN124 are considered the leading standards internationally for Access Covers and Grating. The main differences between the EN and AS standards with the load ratings is the label. European standards (EN1433 and EN 124) are Class A to Class F, however the Australian Standard (AS3996) goes from Class A to Class G. The testing is equivalent, for example, a EN Class F is tested to 900 kilonewtons (kN), and a AS3996 Class G is tested to 900kN)

To keep integrity, SABdrain uses independent testing facilities for all our grates.

How to divert water from a sloping driveway?

Trench drains are a common solution for sloped pavements. They are covered with grates that prevent debris from getting in the drain while also providing a surface for vehicles and pedestrians to travel over.

Driveway trench drains are easy to install, long-lasting, and suitable for almost any driveway. They can even be placed close to the building foundation to prevent water from running in.

What is 5 star antislip?

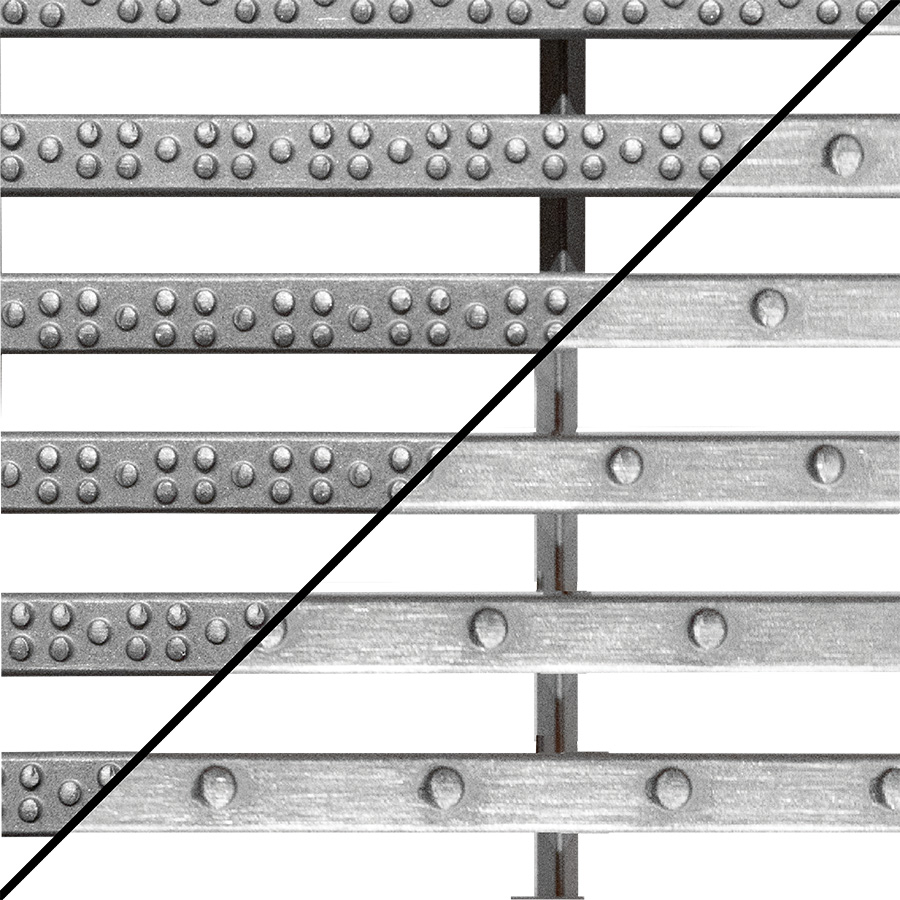

The difference between standard antislip and 5-star antislip grates lies in the slip resistance level: while regular antislip grates provide basic traction, 5-star antislip grates feature specially designed nodules that enhance grip significantly, offering maximum slip resistance ideal for high-risk, wet, or high-traffic areas. Below image shows 922 (5 Star) on the left and 952 on the right.