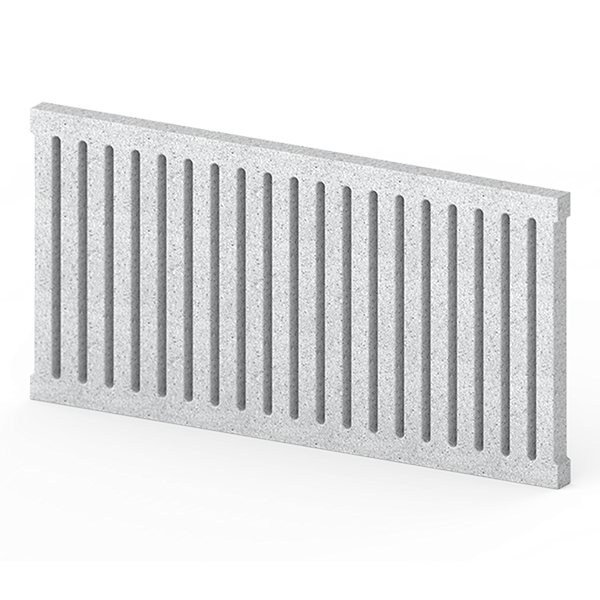

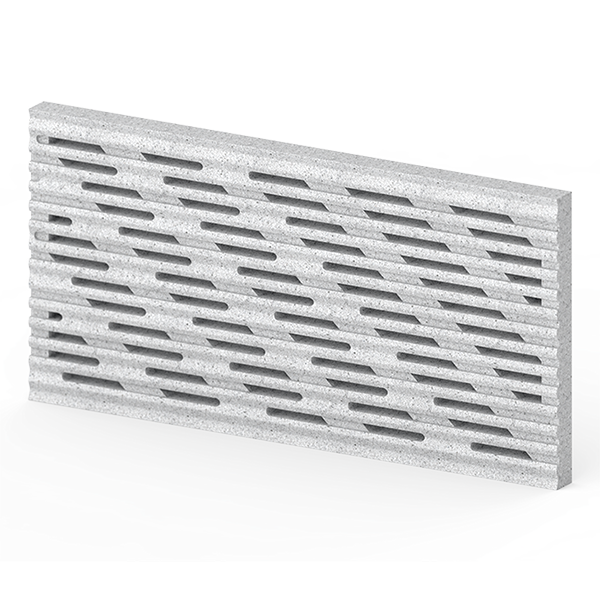

Decorative trench grates made from natural aggregates. Consciously crafted + fully customisable.

A fundamental hardscape design element of any modern city is the drainage system, which protects against flooding by draining excess water away. Now, underground drainage systems are designed to cope with frequent storms where any excess water always travels along the planned drainage flow paths to prevent flooding. Drainage systems are carefully planned to factor in the impact the drainage system has on our natural rivers and creeks. We are preventing waste from being washed into rivers and seas.

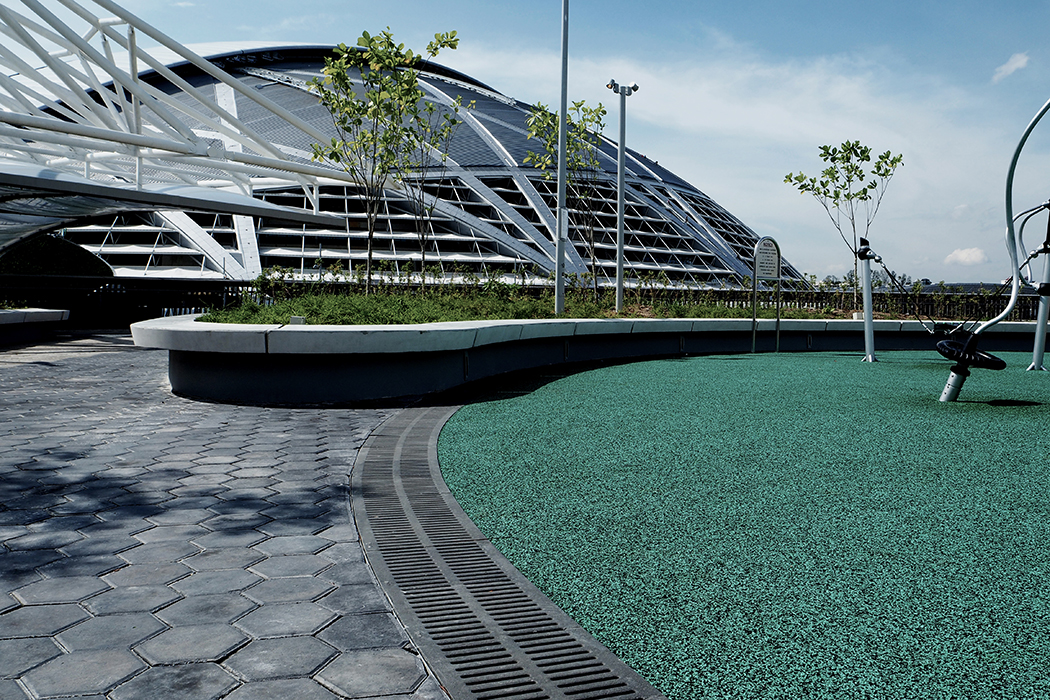

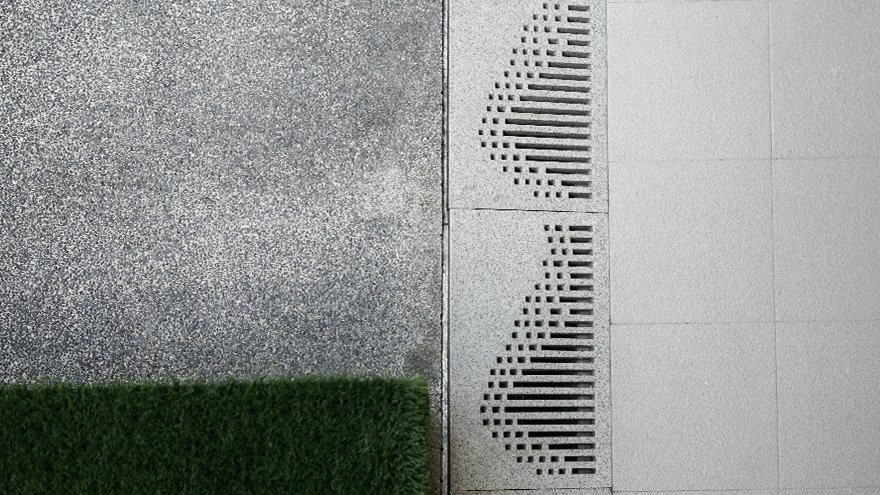

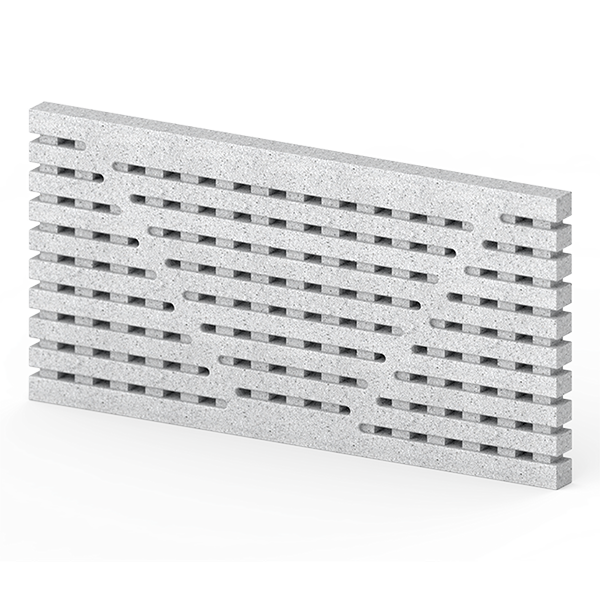

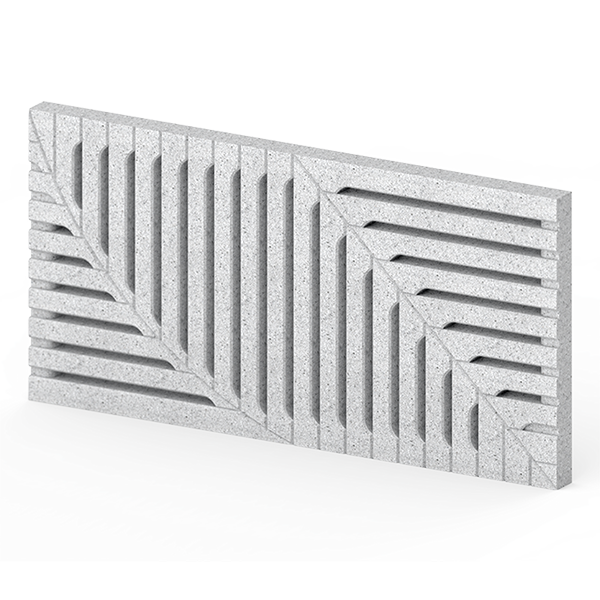

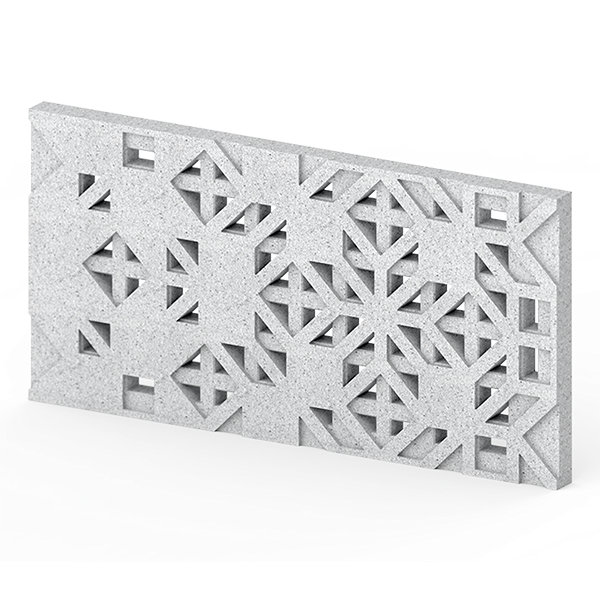

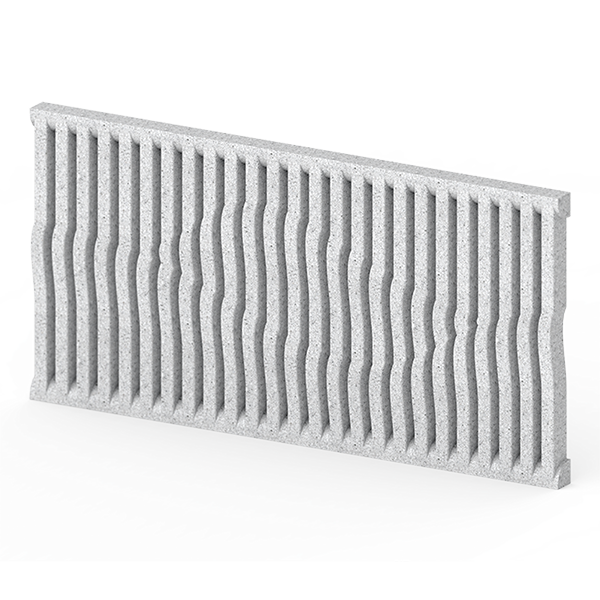

At Jonite, their reinforced stone channel grates and trench grates have redefined the role of gratings and drain covers in the architecture industry. With Jonite channel gratings and trench gratings, outdoor drain covers are more than functional products — they become a cornerstone in your design. They can become design focal points, inviting the viewer’s eye to follow intricate patterns that open up into the building design.

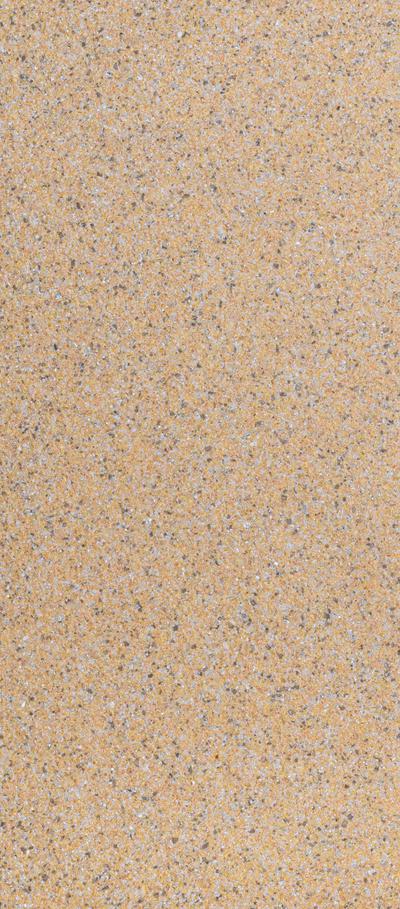

Available Colours

Collections

36 Variants

16 Colours

Custom Options

15 Variants

16 Colours

Custom Options

13 Variants

16 Colours

Custom Options

13 Variants

16 Colours

Custom Options

9 Variants

16 Colours

Custom Options

11 Variants

16 Colours

Custom Options

Design Options

Impressive Materials for Channel Drain Grates

Inspired by aesthetically pleasing stone castles built during the Middle Ages, Jonite sought to transform natural stone into grates. Seven years of extensive research and development produced the world’s first reinforced stone grate for commercial use. They launched the durable and functional product in 1994 and continue to lead in the trench gate industry as the only provider of stone composite products that can compete with metal.

Jonite materials consist of advanced hybrid polymers and 95% natural aggregates. Using at least 30% recycled materials in manufacturing makes our products a sustainable choice. Jonite carries globally recognized green building credentials, such as a Leadership in Energy and Environmental Design (LEED®) certification from the U.S. Green Building Council, for responsible, environmentally friendly use of materials.

With welded materials joined in the stone composite, Jonite grates achieve impressive load-bearing strength and performance. The result is BS EN 124:2015- and 1433:2008 compliant, meeting international guidelines for standard application in areas with vehicles and pedestrians.

Optional Customisation

Frequently

Asked Questions

Can I use Jonite trench grates near my pool?

Yes, you can unless they are within 3 metres of your pool, which Jonite would then recommend Jonite pool grates instead. The main difference is the reinforcements, which for pool grates are a non-ferrous composite material.

How durable are Jonite trench grates?

Jonite trench grates are incredibly durable. We use materials that are rust and corrosion resistant, slip resistant, have a low heat absorption, and high load-bearing performance.

Do Jonite products contain silica?

Jonite has worked hard to ensure their products contain less than 1% silica, which has been accepted by SafeWorkNSW. It is rare that a Jonite product will need to be cut on site. If so, it has to be done with correct PPE.

How durable are stone trench grates in different conditions?

Jonite heavy-duty trench grates are made from engineered stone that’s both strong and durable. All Jonite trench grate covers are designed to handle heavy loads, whether it be vehicles or pedestrians. Plus, unlike some traditional trench grating, it has rust-resistant and corrosion-proof properties, so it’s built to withstand all weather conditions.

Where can I use trench grate covers?

Jonite’s commercial trench grates are versatile enough to be used in everything from driveways, and poolside areas to public walkways and parks. All Jonite trench grating has different load ratings, making it suitable for use in heavy vehicle zones as well as pedestrianised areas.

Does Jonite offer load-rates, heavy-duty trench drain grates for vehicles?

Jonite trench grate covers are designed to handle vehicular loads and are compliant with BS EN124:2015 standards. Our load-rated drainage grates are available up to load class D400, making them suitable for heavy-duty applications such as commercial driveways, car parks, and other hardstanding areas.

Are Jonite trench grates slip-resistant?

The matte finish of Jonite trench grating means it is naturally non-slip. Jonite has conducted Pendulum and Ramp tests on all trench grate covers to make sure they meet industry standards for slip resistance. With a class V on the Pendulum test and an R10 on the Ramp test, Jonite drainage grates can handle most locations and applications.

How sustainable are stone trench grates compared to traditional trench grating?

Jonite use at least 30% recycled aggregates in their stone grating products, which reduces carbon emissions by up to 80%. All Jonite decorative grating is Singapore Green Building Product (SGBP) certified (4 ticks, leader). This means when you choose Jonite stone trench grates, you can score additional points under the Functional Systems Criteria (Flooring, Ceiling, Roof, External Wall, Internal Wall and Door systems) and/or Singular Sustainable Products outside of Functional Systems Criteria.

Does Jonite offer ADA-compliant drain covers?

All Jonite trench grates are Americans with Disabilities Act (ADA) compliant. Plus, their entire range of trench grate covers is capable of handling heavy loads and is ideal for spaces with strict BFA (barrier-free access) requirements.