Cargo ports and container terminals are the gateway to vital international trade, with over 8.6 million twenty foot containers exchanged at Sydney, Brisbane, Melbourne, Fremantle and Adelaide in 2022-2023.

Infrastructure in, and around the terminal requires sufficient surface water drainage systems to prevent operational disturbances from ponding or flooding.

Requirements for Container Terminals/Ports Drainage Systems

Exposure to extreme loads & dynamic forces

Forklifts, tractors and other heavy goods vehicles are used to move and transport shipping containers, which can have a load capacity of up to, and over, 100 tons.

Drainage systems in these areas must have the ability to cope with the extreme loads that are running over them. Systems should be robust and secure to withstand not only the loads, but dynamic forces from vehicles braking, turning or accelerating over the drain.

Exposure to extreme loads & dynamic forces

Each port or container terminal has different traffic volumes, with Western Australian ports loading 1004 million tonnes of maritime cargo in 2020/2021, and NSW loading 289 million tonnes. This should be taken into consideration when specifying drainage solutions to ensure the system is suitable for large amounts of heavy traffic.

Potential Contamination

Some chemicals or surface pollutants may occur as a result of port operations. Fuels, oils, metals, microplastics, rubber particles or potentially hazardous substances from spills may deposit on the ground, washing into drains. It’s important to select a drainage system that is chemical resistant to prevent damage.

Corrosive Environment

Channel drainage systems installed in cargo areas may be exposed to corrosive elements such as saltwater, high humidity, extreme temperatures, strong UV radiation, fuels or more.

Extensive Surfaces to Drain

Large flat surfaces and heavy rainfall/extreme weather conditions can produce high volumes of surface water run off. High capacity drainage systems with accurate hydraulic calculations will entire surfaces are reliably, efficiently drained.

Drainage Solutions for Container Terminals/Ports

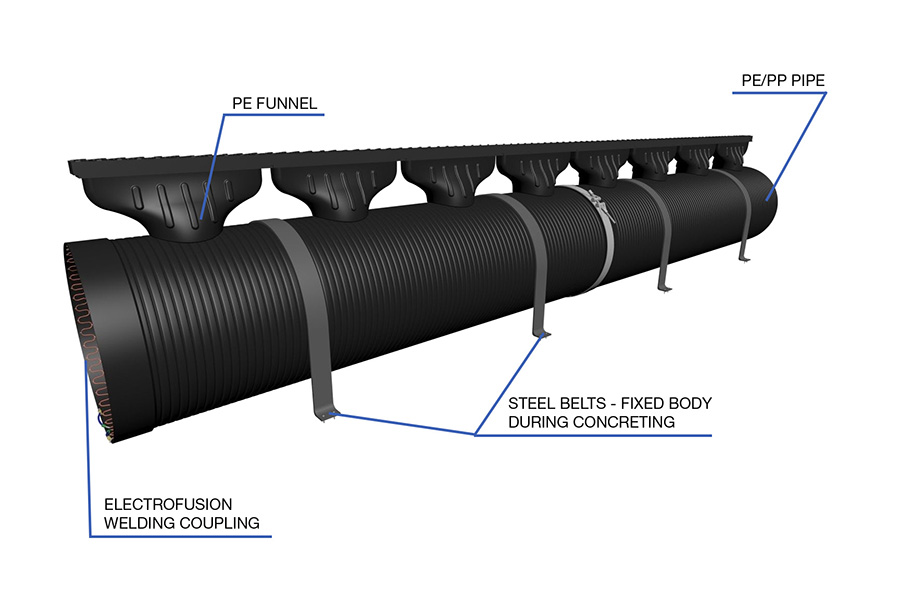

High Flow Slot Drain

- Fast and easy installation

- High strength

- Saves money and time

- Metal retaining clamps - stabilize position during the concreting process

- Electric welding machine provided for installation

- Ability to be sloped

- Suitable for collecting and transporting rainwater

- Slot drainage and collector in one system

- Lightweight compared to concrete or metal

- Excellent watertight connections by electrial welding

- Length up to 6M (standard sizes 2M) - fewer joints required

- One concrete pour

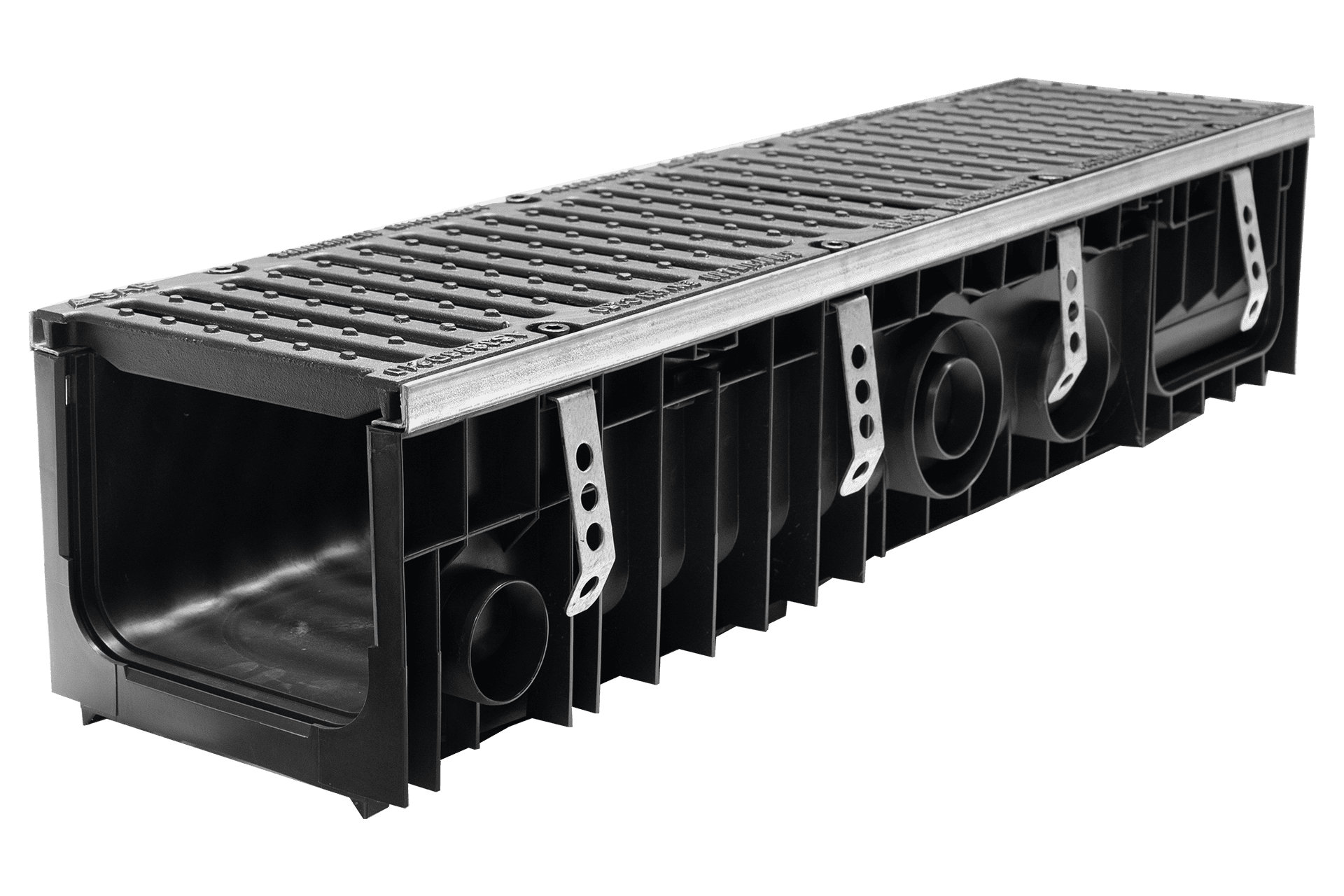

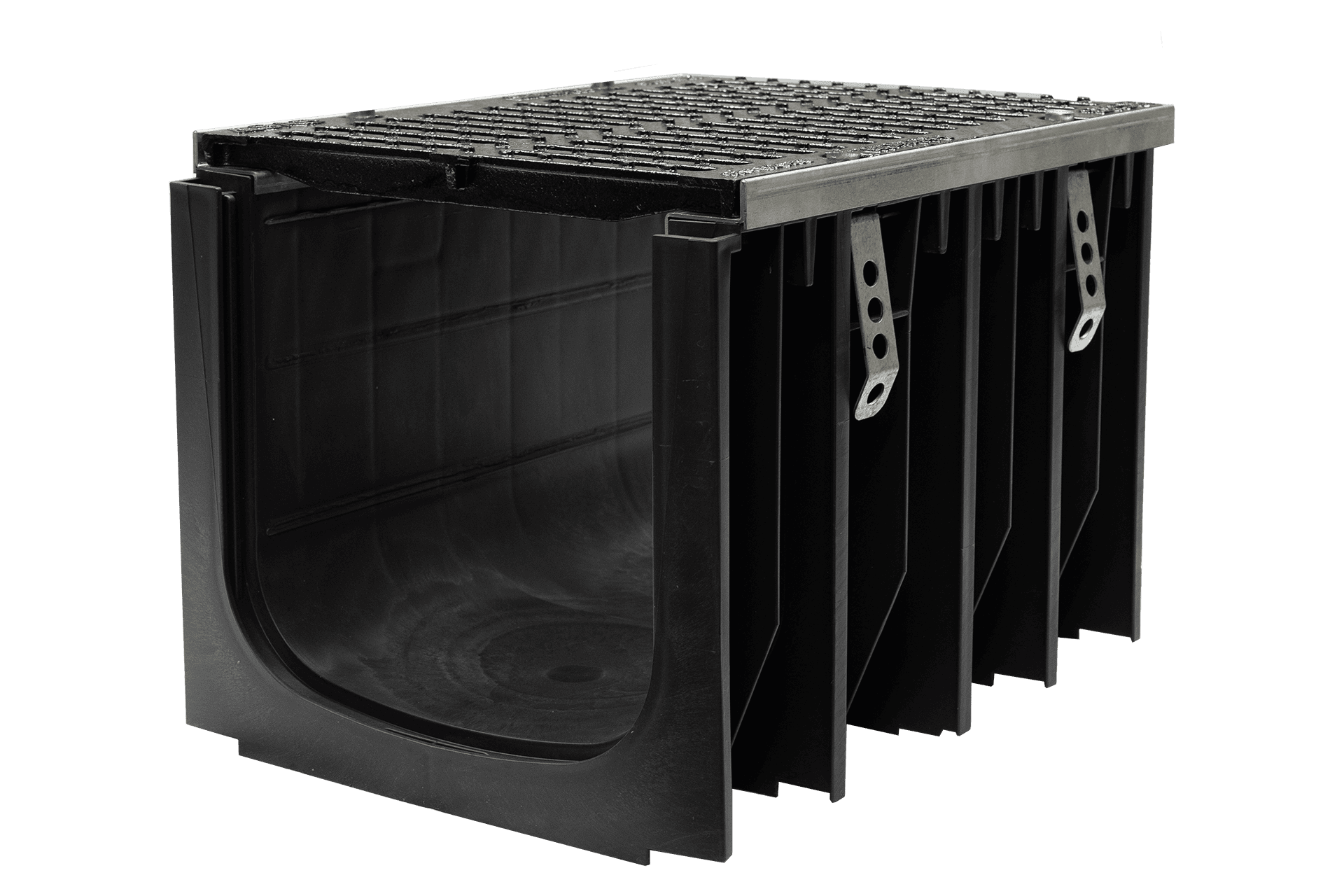

SABdrain 706

Polypropylene channel with Class G rated cast iron grates. Each high strength cast iron grate is equipped with 8 point security fixings system. Supplied with steel support edging to guarantee higher performance for heavy loads and high wheeled vehicles. SABdrain 706 is designed for aircraft traffic, loading docks, container terminals, military, mining and all hard wheeled vehicles.

Drainage Solutions for Harbours, Quays and Cruise Passenger Terminals

SABdrain has a wide range of linear drainage systems suitable for marine, coastal and other waterside areas such as parks, walkways, marinas, harbours or terminals for cruise ships and ferries. Choosing materials that are suited to specific environmental conditions is critical. In challenging settings, such as marine environments, it’s important to use corrosion-resistant materials like stainless steel, aluminum, or coated metals. Components and fasteners should be made from the same or compatible materials to reduce the risk of galvanic corrosion; it’s advisable to avoid pairing highly dissimilar metals, like copper with aluminum or steel.

These areas require surface drainage solutions with specifics such as:

- Safe, durable system designs for public areas with heavy pedestrian traffic

- Corrosion resistant materials for long term durability

- Aesthetic design to match public areas

- Ease of installation to minimize traffic interruptions