Drainage grates play a crucial role in maintaining the proper functioning of a drainage system. They prevent debris, trash, and other materials from clogging the drain, allowing water to flow freely. However, over time, drainage grates can become damaged or broken due to wear and tear, weather conditions, or even vandalism. If left unrepaired, broken drainage grates can cause flooding, property damage, and even pose a safety hazard. To ensure that your drainage system remains efficient and effective, it’s important to promptly replace broken drainage grates. In this article, we’ll discuss the steps you can take to correctly identify and the process of replacing broken grates to ensure that your drainage system is operating at optimal levels.

Should I Replace My Trench Drain Grates?

If you are not proactive, and take steps to replace your trench drain grates as soon as damage is apparent, it can lead to larger, more costly issues. One of the most severe consequences of poor driveway drainage is damage to the foundation of your home. When water is not adequately diverted away from the driveway, it can seep into the ground around your house. Over time, this excess moisture can erode soil supporting the foundation, leading to cracks and potentially structural instability.

When to Replace Trench Drain Grates

Trench drain grates could fail for several reasons. They age with time, and the structure of the material breaks down.

Poor maintenance can also cause drain gates to fail sooner than normal. Drain grates wear out even faster if they don’t meet the specifications for your use.

A proper trench drain grate replacement can help you solve drainage issue

Replacing Broken Grates

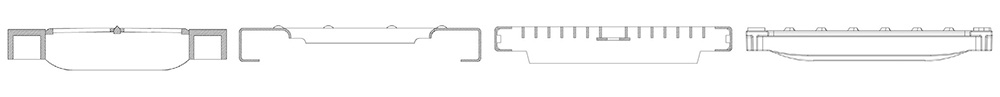

Measuring

Grate

- Width at top of grate (take note of whether the grate has an edge that covers the side of the channel)

- Height of grate

- Width of underside of grate

- Height of underside of grate

- Grate length

Channel

- Internal Width

- Internal Height

- External Width

- External Height (if accessible)

- Edge of channel

Identifying The Grate Material

Manufacturers Mark