Frequently Asked Questions

Refine our faqs to a category:

Minimum Impact Disposal – Can Jonite be recycled? Can it be broken down?

Jonite can be crushed and broken down into smaller aggregates as road base.

Is there a minimum order for custom items?

No

Where can I purchase SABdrain?

We have over 800 distributors Australia wide. Find your nearest one here.

Alternatively, contact us & we can assist you.

Jonite Lead Times

Average lead time is 12-14 weeks. Please contact us to confirm lead times as this can vary.

Do plastic channels warp in concrete?

Once polypropylene channels are encased in concrete, they are rigid. Warping or bending is due to incorrect installation, such as concreting with no grate installed.

How wide or deep does my trench drain need to be?

This will vary based on slopes, rainfall, weather patterns and location of the drain.

Use our partners tool here to design your system, or contact us for assistance.

Is 601 heel guard?

Yes, the aperture of 601 grate is 8mm.

What are Jonite products made from?

Jonite products are made from reconstituted stone. Created from 95% natural aggregates and advanced hybrid polymers, Jonite products provide a finish which is both luxurious and natural to the touch.

The technical specification of the core material used is: 95% agglomeration of natural stone substrates & mineral oxides formed under a proprietary vacuum and compression process. Composed of a proprietary structural polymer hybrid system of a heterogeneous blend’

The core material is made of 95% natural aggregates like crushed natural granite etc. 5% comprises of a hybrid blend of epoxy resins.

Reinforcements within products are flat steel bars of varying thickness. They are welded into frames and treated with a coat of protection before being incorporated.

Why are there so many grate options?

Most of a trench drain system is underground and mostly invisible, apart from the grate. Aesthetics aside, the grate must work together with the channel to provide the right load classification performance (AS 3996). For aesthetics, grates come in a variety of different materials such as ductile iron, galvanised steel, stainless steel, non-ferrous metals and plastics. Each material has differing load class ratings.

Learn more about designing for inclusions & disability. Grates that comply with the requirements for pedestrian & cycle areas (AS 3996 & AS 4586) and disability access are available (AS 1428.2).

Is Jonite sustainable?

Jonite is on a mission to lead the way towards a greener future. This is why everything Jonite does starts with sustainability in mind. All Jonite products are proudly made of at least 30% recycled materials. Unused products don’t go in the trash. Steel and stone that meet their strict requirements are recycled so they can be used again as raw materials.

Learn more here.

How well do Jonite trench grates hold up under extreme weather?

Specified in projects all over the world including Dubai, Singapore and various states in the United States, Jonite has been used in the hottest, coldest and most humid places in the world with no known problems.

What is the fastest drainage system to install?

The SABdrain system is up to 40% quicker to install than standard polymer channels. With an installation time of 10M per hour, compared to just 6M per hour. CPB Contractors used just 60% of their allocated installation time when installing SABdrain on Northern Road Stage 5.

What is polypropylene?

Polypropylene is a thermoplastic polymer that offers numerous benefits, including high chemical resistance, durability, and flexibility. These qualities make it an ideal choice for drain channel applications in various industries, such as food processing, automotive, and pharmaceutical.

Are polypropylene trench drain systems weather resistant?

Polypropylene drainage channels are known for their exceptional durability and strength. The material is highly resistant to corrosion, chemical attacks, and weathering. This means that it can withstand harsh environmental conditions, heavy loads, and extreme temperatures without deteriorating or compromising its structural integrity. Unlike traditional drainage materials such as concrete or metal, polypropylene channels are less prone to cracking, rusting, or weakening over time, resulting in a longer lifespan for your drainage system. The advanced construction of SABdrain drainage channels gives it greater structural rigidity, protecting it from damage during and after installation.

Will cast iron grates rust?

Like most metals, cast iron goes through a natural oxidation process, resulting in an outer protective coating known as rust. This process is called Patina. Patina is a naturally occurring process and shouldn’t be confused with corrosive rust.

The two conditions that cause cast iron to rust are:

- Moisture (Cast iron will begin to patina when the relative humidity exceeds about 64%.)

- Oxygen

Factors that accelerate rusting:

- Carbon Dioxide

- Acids

- Impurities

Like most metals, cast iron goes through a natural oxidation process, resulting in an outer protective coating known as rust. This process is called Patina.

Patina is a naturally occurring process and shouldn’t be confused with corrosive rust. Patina is good for iron as it provides a protective layer. A metals patina is a thin layer of oxides on the metal that acts to slow down further corrosion. Therefore patina on cast iron grates does not harm the structural integrity. This rust layer shields the cast iron from further oxidation. Think of rust as a corroded armour that protects against additional corrosion. This property allows iron to remain strong & intact for several decades. Unlike steel, cast iron is durable and will not flake. The patination of cast iron grates is predictable, and the duration of each stage depends on local moisture conditions, foot traffic, foreign substances etc.

Once the oxidation process begins, cast iron will turn a bright orange and then fade to a chocolate brown, similar to the colour of manhole covers.

Rust cannot be prevented but the process may be slowed by introducing a buffer material between the iron and atmosphere. Linseed oil can be applied to the grates prior to installation. Another common practice is to spray or powder coat the grates. This coating must be reapplied whenever there is chipping to maintain rust protection.

Can I conceptualise and design a completely unique street bench?

Yes, this is possible.

Load Classes Explained

The load rating of a grate is a specification of the amount of weight the grate can withstand.

Residential- Will withstand 1.5 ton wheel loading. Footpaths & driveways.

Class A – 330kg nominal wheel loading. Pedestrians, cyclists.

Class B – 2,670kg nominal wheel loading. Driveways (cars & light commercial vehicles)

Class C – 5,000kg nominal wheel loading. Areas with slow moving traffic (shopping centres). Heavy commercial vehicles.

Class D – 8,000kg nominal wheel loading. Highways & roads, lightly loaded forklift, warehouse

Class E – 13,700kg nominal wheel loading. Commercial heavy wheeled traffic, hard wheeled forklifts, construction/military/mining vehicles

Class F – 20,000 nominal wheel loading. Docks, wharves, airport taxiways

Class G – 30,000 nominal wheel loading. Extra heavy duty, airport runways, docks

View our guide to load class classifications here.

What sizes are available?

Our channels range from 100mm x 50mm – 500mm x 500mm

What are the best trench drains for airports?

SABdrain has a range of trench drains suitable for all areas of an airport, from pedestrian areas to runways. Innovative systems that can meet the extreme demand of airports. Discover more about airport drainage here.

How does Jonite pool grates compare to natural stone cut pool grates?

It may be tempting to use the same stone flooring to cut slits or puncture holes and use them as a grate. However, they are a nightmare for maintenance as most are not strong enough even for pedestrian traffic. Some may overcompensate the strength with a much thicker slab, but that would only make the grate too heavy.

What are the different types of trench drains?

Trench drain systems utilise a simple angled slope on both sides of a linear trench to move runoff into a channel. Liquids are then discharged at the end of the drainage channel into an underground pipe system or culvert. Trench drains generally require a shallower excavation than in-line pits with extensive underground piping.

Cast-in-situ systems are another type of trench drain design. This method uses extensive formwork and labour required. A form is built and concrete is poured around it to form the trench. Forming channels onsite drives project costs up dramatically due to labour time.

Are Jonite tree grates suitable for vehicular applications?

Jonite current standard models can sustain loads of up to 5KN, which is strictly for pedestrian application. However, Jonite can customize the tree grates’ design and the support frames for a specific load class. Please note that the support for the tree grates needs to be certified by a professional engineer to sustain the particular load class.

How durable are Jonite tree grates compared to cast iron tree grates?

Jonite tree grates, like all Jonite products, are made of a proprietary stone composite material with unique properties. When correctly installed, the material ages very similarly to natural stone but excellent UV and weather resistance. However, unlike cast iron, the material does not rust with time and is outstanding for many applications.

What are the different types of surface drainage?

Different types of surface drainage solutions includes in-line pits, open swales or grated trench drainage. Cost comparisons have shown modular trench drains to have lower total installed costs when labour, excavation, pipework, grading etc., are taken into account. Furthermore, heavier materials such as polymer concrete will drive up labour and transport costs.

Discover the advantages of using polypropylene instead of polymer.

How durable are Jonite trench grates?

Jonite trench grates are incredibly durable. We use materials that are rust and corrosion resistant, slip resistant, have a low heat absorption, and high load-bearing performance.

How does a drainage system work?

A trench drainage system is an linear drainage system used to remove excess surface water from an area, by use of a channel & grate. Without a drain, water can pool- potentially leading to damage to building foundations, driveways, and other structures.

Linear drains rely on gravity to remove water from where it pools. When thinking about installing a drainage system, run length, slope & sizing need to be discussed with your installer or designer.

Should grates be installed before concreting?

Yes, it is extremely important to prevent bowing when concreting. It is impossible to install a grate if the channel has bowed after concrete has set.

A great tip is to use a temporary grate (like timber) to avoid concrete spill on the grates if possible. Ensure there is no bolts/lockdown that needs to be secured before concreting)

Can Jonite tree grates be expanded for growing trees?

Not all tree species need this feature, but if you do, Jonite has selected models like their ADA Collection, which offers up to 4 different inner diameters (390/460/530/600mm). Should you need even more expandability, some models like the Square Slots can expand even beyond that. Contact us for better advice on this.

What removes tea stains from stainless steel?

White vinegar is effective for helping remove or reduce tea staining from stainless steel.

Learn more about the process here.

Can Jonite Ventilation Grates be customized for vehicular applications?

Yes, this is possible. However, the open area and design of the grate may be limited, similar to a customised trench grate.

Does SABdrain only supply trench drain?

SABdrain Australasia has a wide range of stormwater drainage solutions and architectural products such as breeze blocks. We are proud to offer niche or custom drainage solutions for projects, as well as other solutions such as cable troughs.

To find out more, click here

How durable are Jonite pool grates near chlorine pools or fountains?

Jonite pool grates are specially designed to be resistant to chlorine. On top of that, it contains reinforcements made of a non-ferrous composite material which prevents it from rusting but at the same time, providing excellent compressive strength while being lightweight.

What is the difference between 304 and 316 stainless? Which should I use?

A 304 stainless steel drainage grate and a 316 stainless steel drainage grate differ primarily in their composition and corrosion resistance. 304 stainless steel is a versatile and commonly used grade known for its excellent corrosion resistance in various environments, making it suitable for many applications.

316 stainless steel contains higher levels of chromium and additional elements like molybdenum, which enhance its resistance to corrosion, particularly in harsher conditions such as marine environments or exposure to chloride-containing solutions.

Within a kilometre of breaking surf, 316 stainless is recommended to be utilised. Additional care will still need to be undertaken to prevent tea staining. See more about the maintenance of stainless steel here.

What is a modular trench drainage system?

Modular trench drainage channels are typically manufactured in metre or half-metre lengths for easy transport to the job site, on-site handling, and versatile configurations. Modular channels usually start at 100mm wide. These narrower widths use smaller grates, significantly reducing overall project costs. Wider systems can be supplied if required by hydraulics or application.

Where are Jonite products made?

Jonite is based in Singapore. SABdrain stocks a limited range. Contact us to find out more.

What is the difference between a sump cover and trench grate?

The most significant difference is that a sump cover is designed for point drainage systems while trench grates are used for linear drain systems. In most cases, point drainage is more inexpensive as you use fewer grates.

Can I use Jonite pool grates if my pool is not an overflow pool?

Absolutely. Jonite pool grates are excellent for pool decks because not only do they help drain water and prevent dirty water from entering the pool from maintenance, they also create an aesthetical feature with its appealing designs.

Is there a minimum order quantity for custom tree grates?

No. Jonite is more than happy to customize one set of tree grates.

Why is surface drainage important?

Standing or ponding water in and around buildings or on roads can cause severe structural damage to foundations, building materials and other structures so it’s important to utilise surface drainage solutions to divert it quickly and efficiently. Surface drainage is also crucial to help prevent hydroplaning on roads, highways, bridges and airport runways.

Effective handling and transporting away stormwater during, and after storms is a vital element in facility and road construction planning.

Discover the SABdrain advantages – click here

Can Jonite design the support if I were to customize the panels for the bench?

Jonite can design a simple panel support system. However, please take note that any mounting or fixtures will not be included in the design.

How do you keep cast iron from rusting?

Cast iron undergoes a natural oxidation process, resulting in an outer protective coating known as rust. This process is called ‘patina’. Patina cannot be prevented but the process may be slowed by applying various coatings or treatments to create a barrier between the metal and environmental factors.

Is there an alternative to polymer drains?

Yes, SABdrain drainage systems are an alternative supplier for drainage solutions. SABdrain utilises polypropylene channels over polymer. Polypropylene is a thermoplastic polymer that offers numerous benefits, including high chemical resistance, durability, and flexibility. These qualities make it an ideal choice for drain channel applications in various industries, such as food processing, automotive, and pharmaceutical.

One of the key advantages of polypropylene trench drain channels is their ability to withstand harsh chemicals commonly found in industrial environments. This resistance to corrosion ensures a longer lifespan for the drainage system, reducing maintenance costs and downtime. Additionally, polypropylene channels are lightweight and easy to handle during installation, making the process more efficient and cost-effective.

What is the grande series?

The SABdrain grande series simply refers to any product where the width of the channel is larger than 300mm internally

What is the life cycle of Jonite products?

The general life cycle of Jonite products is minimally 30 years or more

How do Jonite Breeze Blocks compare with traditional concrete blocks?

The comparison reveals many advantages. Regular concrete blocks are commonly found in raw concrete colors, and colored variations often appear largely synthetic. In stark contrast, Jonite Breeze Blocks are significantly more durable, owing to their exceptionally low water absorption capacity and self-cleaning capabilities, making them far more durable than traditional concrete breeze blocks. With high compressive and tensile strength, Jonite Breeze Blocks are substantially stronger than concrete blocks, expanding their potential applications.

Will stainless steel rust?

Despite its anti-rust properties, you may see some stainless steel that appears to have rust on the surface. This is known as tea staining. Tea staining is rust forming on the surface of stainless steel, causing a discolouration similar to a tea stain. It may not look appealing, tea staining is only cosmetic and does not affect the functionality or integrity of the stainless steel. Regular cleaning and maintenance with a mild soap and water solution can remedy the discolouration.

Is Hydropro watertight?

The system achieves high watertightness and bond strengths through the use of electric welding during installation.

How much does a drainage system cost?

The cost of a drainage system depends on the materials used, and the size. A system with a wide stainless steel grate will be more expensive than the same size with a polypropylene system. Reducing the width of your grate will help reduce costs.

SABdrain channels have a greater flow rate (up to 18% faster), therefore reducing the size has less impact on efficiency.

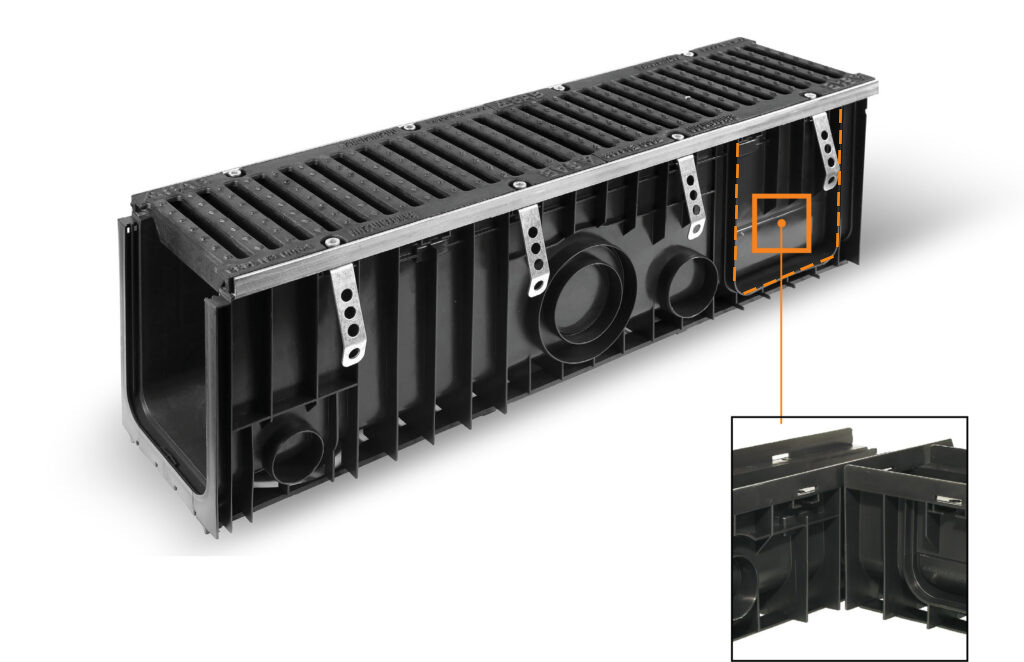

How to create a corner/90 degree angle with SABdrain channels?

SAB channels have preset lateral connection for 90 degree joining of 2 channel units together. Allows right angles, corners, tees & crosses without any additional fittings.

SAB channels have preset lateral connection for 90 degree joining of 2 channel units together. Allows right angles, corners, tees & crosses without any additional fittings.

Cut out the highlighted section above & join the channels.

How do you lift a SABdrain grate cover?

Most grates require the locking mechanism to be unlocked, before gently lifting the grate out of the channel. Ensure to not bend the grate. Keep components in a safe place if the grate is being placed back in the channel.